INTRODUCTION

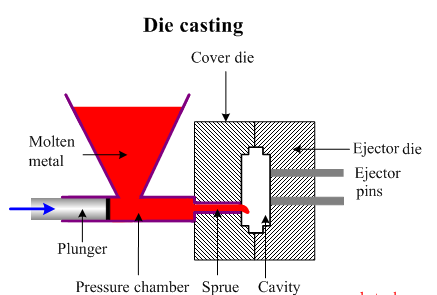

The process of die casting traces back to the 1800’s. It was in 1838 that the first die casting equipment was invented to produce parts for the printing industry. It was later patented for mechanized printing type production. The use of die casting equipment was limited to this industry for a couple decades before it became an integral component in the production of parts for other products like consumer goods and appliances.

Its ability to efficiently produce parts with intricate and complex shapes with incredible accuracy and to repeat the same mold many times over is changed the manufacturing world forever. From then on, the uses for die casting grew dramatically, as did the technology. The actual term “die casting” does not have a complicated explanation. It basically comes directly from the process itself. It will be easier to start a little backwards, explaining “casting” first, and then “dies.”

Advantages of die casting:

- High productivity.

- Good surface finish.

- Thin wall parts may be cast.

- Very economical process at high volume production.

- Fine Grain structure and good mechanical properties are achieved.

- Intricate shapes may be cast.

Disadvantages of die casting:

- Not applicable for high melting point metals and alloys (eg. steels)

- Large parts cannot be cast.

- High die cost.

- Too long lead time.

- Some gases may be entrapped in form of porosity

OBJECTIVE

As we know there are few disadvantages that is the major concern for moulded material as it can reduce the lifetime of that material due to porosity. Also this helps us to get the required volume with the help of Arduino.

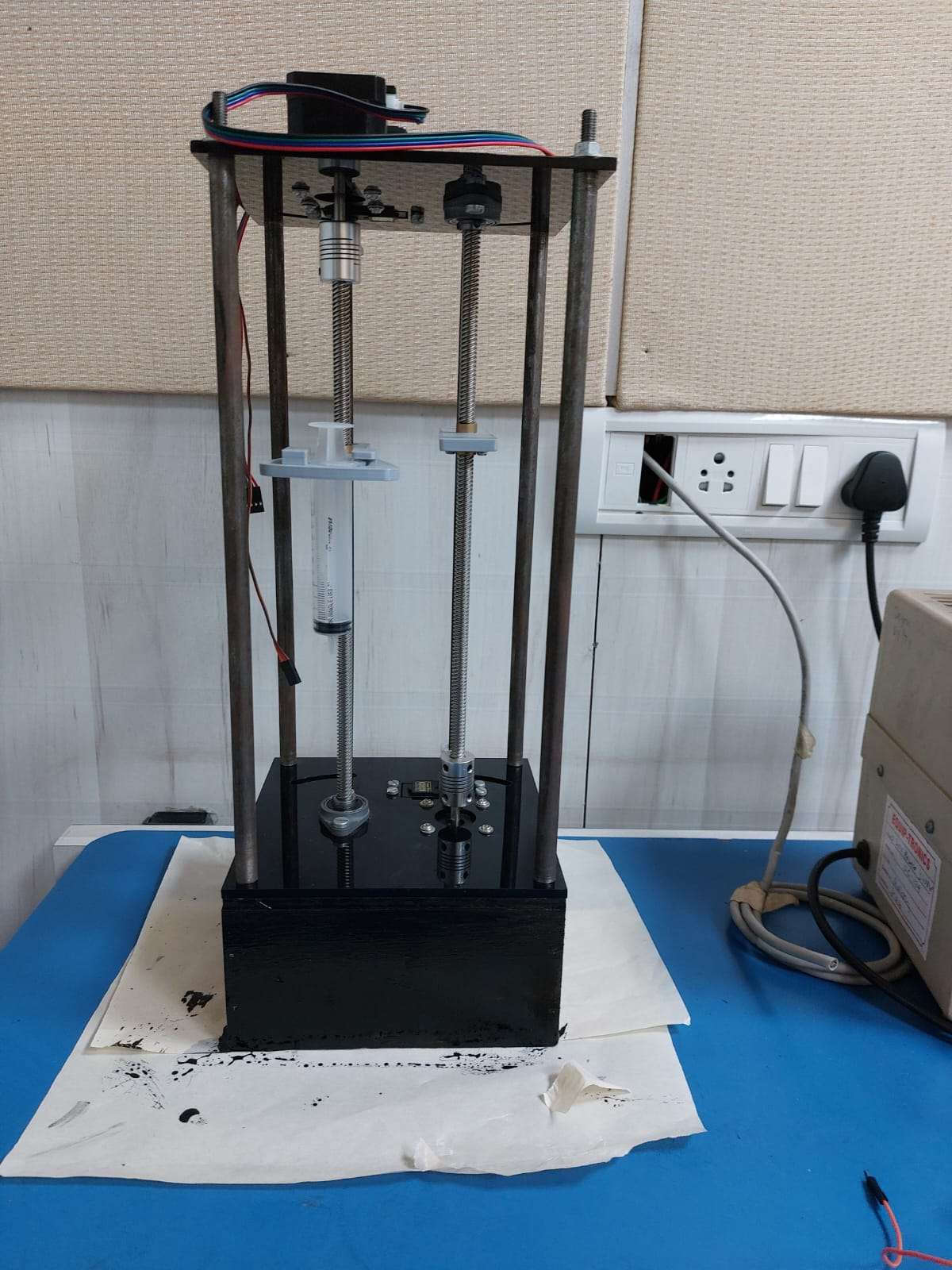

My model ANTI- GRAVITY FILLER mainly focuses on reducing the porosity. It works under the theory of non-gravitational field(Anti- gravity)..png)

As we know that the gravity is proportional to air so in this case I am filling it against the gravity so the probability of air inside will be reduced. Hence, decreasing the porosity and increasing its lifetime of the material.

ADVANTAGES OF THIS MODEL:

- Negligible amount of air bubbles.

- High productivity.

- Good dimensional accuracy.

- Good surface finish.

- Thin wall parts may be cast.

- Very economical process at high volume production.

- Fine Grain structure and good mechanical properties are achieved.

- Intricate shapes may be cast.

- Small size parts may be produced.

- Get précised volume as required.

CONCEPT AND OVERVIEW

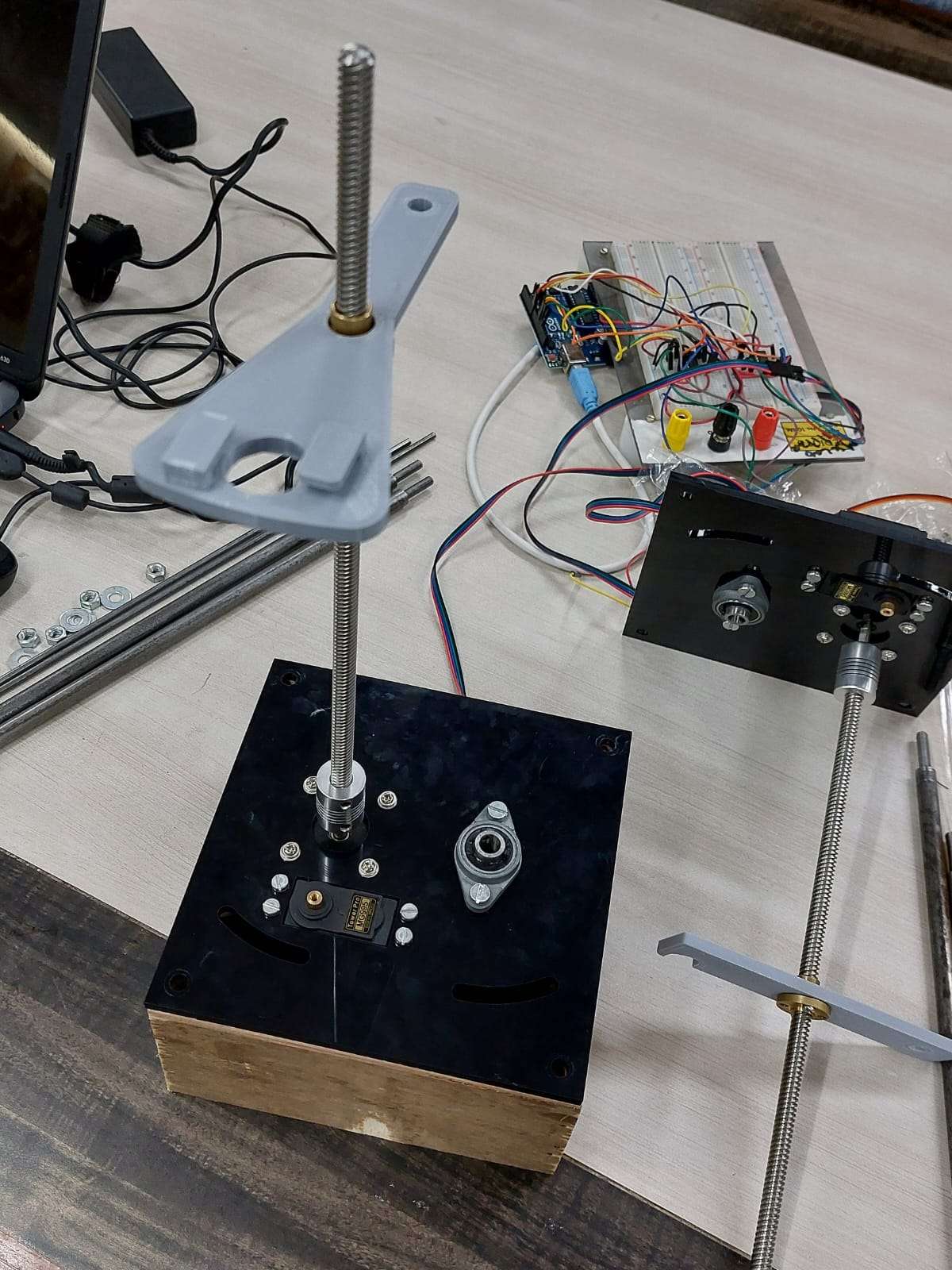

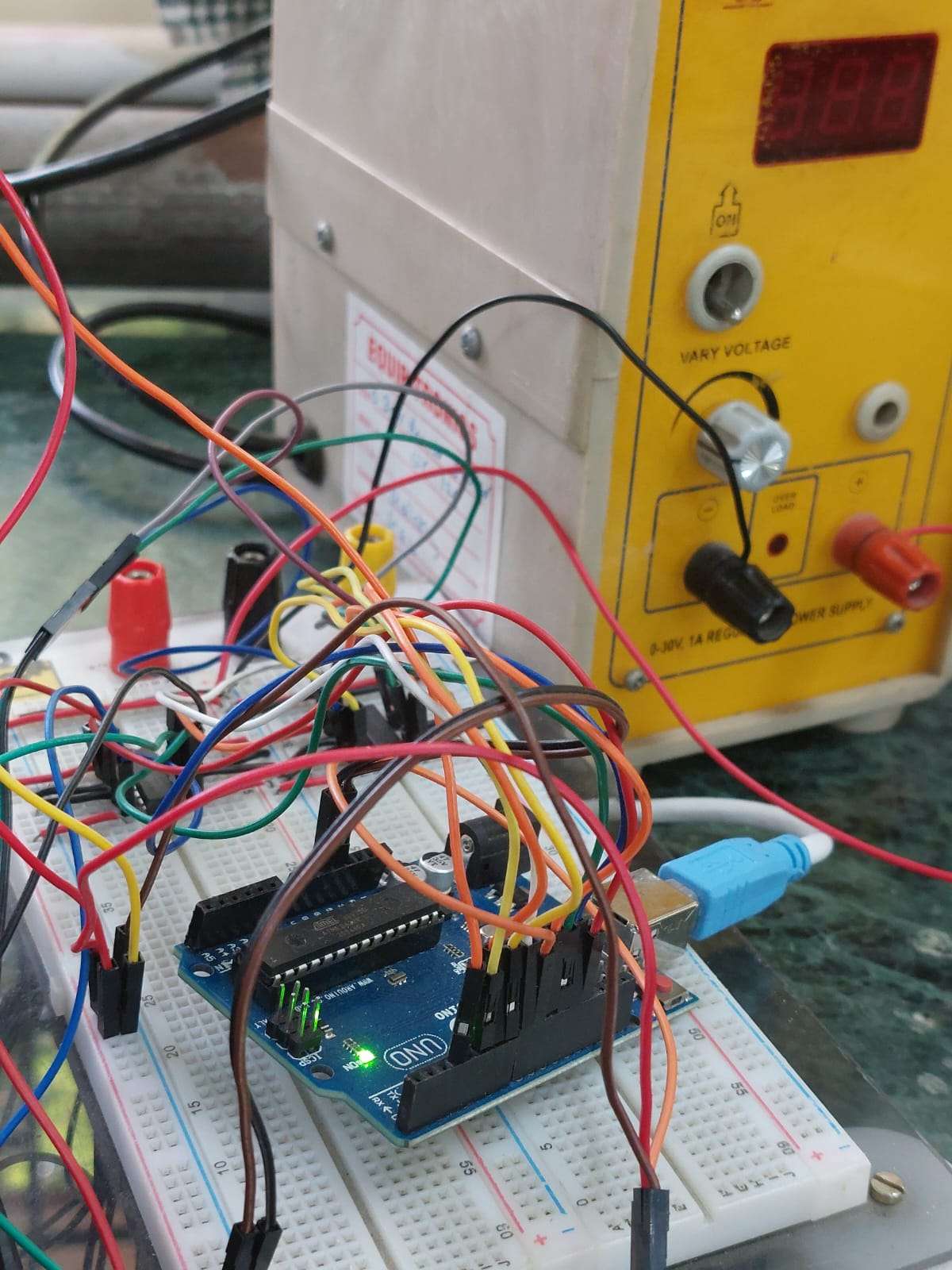

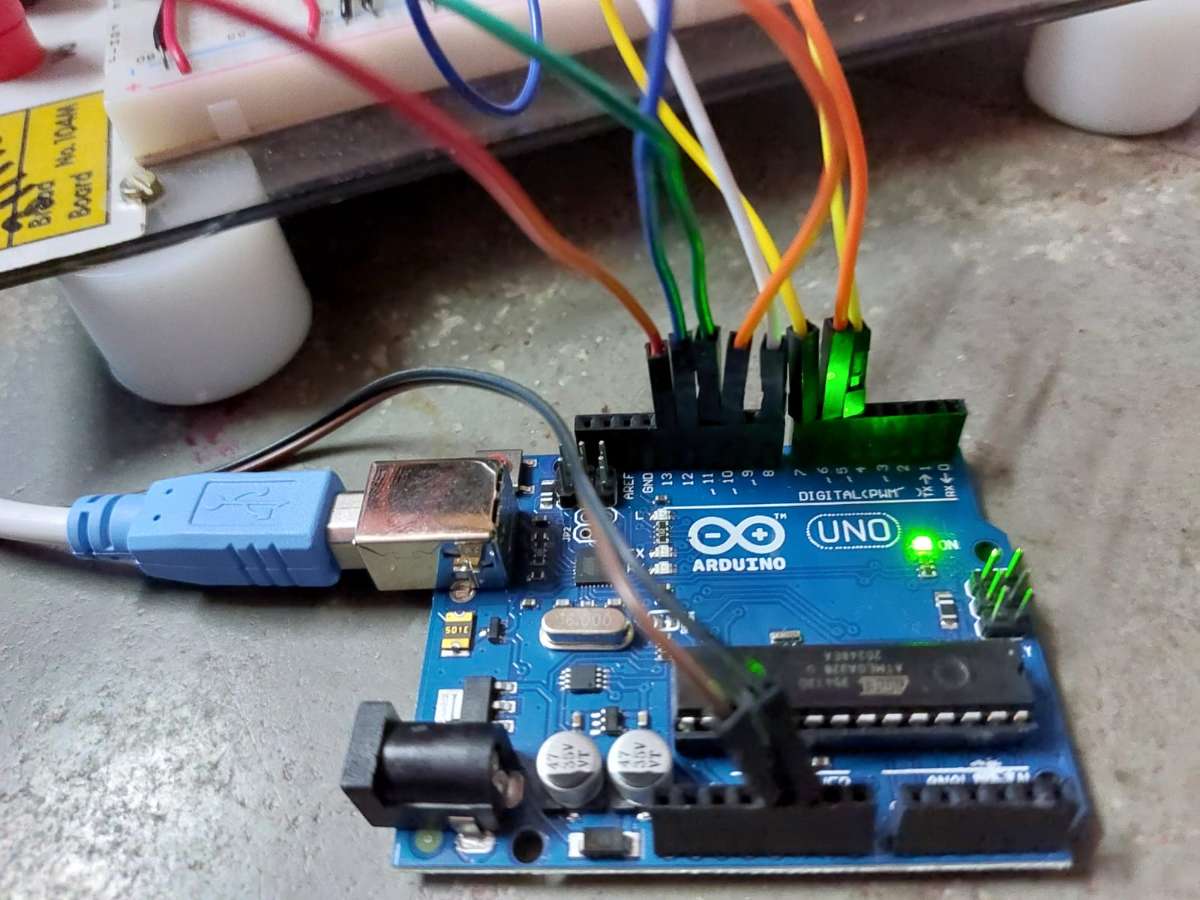

The system is controlled by an Arduino which is interfaced with stepper and servo motors.

Nema 17 stepper motors are used for linear motion and MG 995 servo motors are used for angular motion of the mounting plate.

Since both nema 17 stepper motor can have back current and can damage the arduino therefore I am using L293d motor driver IC. And also I am providing external 5v power supply since I have to power servo too. So, my servo is being powered using arduino’s 5v power supply.

CIRCUIT DIAGRAM

.png)

ADVANCEMENT

If the same model is rotated 180° upside down you can see that the injection will be stable and just the suction part is going to be used for filling so it will be filling against the gravity and the die is placed above the injection.

To make the model for industrial use we need to modify by changing:

1. We can use linear actuators instead of lead screw.

2. Customised hydraulic cylinders instead of syringe.

3. To get different amount of volume, we can code accordingly.

4. We can also interface touch screen to make it user-friendly.

APPLICATIONS

It can be used in die casting industry.

Filling industries.

Model in making

Final look

Circuit connections

.jpeg)