Video

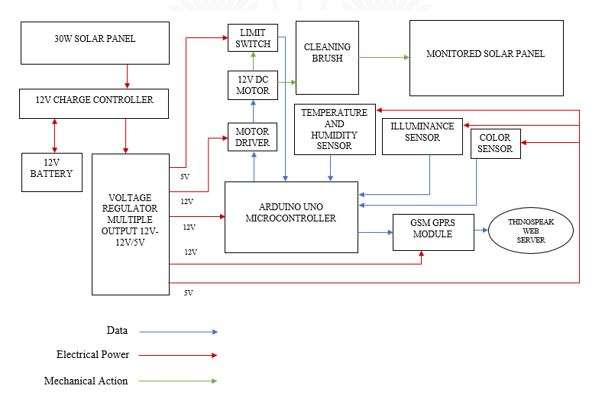

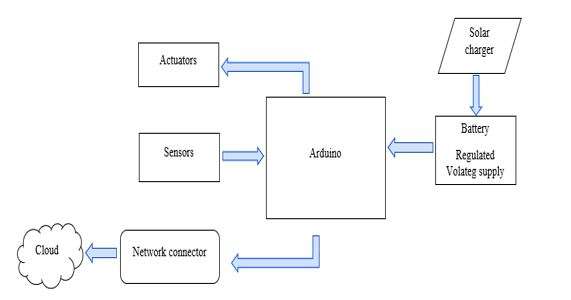

The system is connected to a standalone DC power supply to ensure a steady load(s) electricity supply; this will automatically regulate the voltage compatible with the component devices. The Arduino Uno controller was programmed to continuously and consistently read sensor data and, in case of a need to clean, react by sending a signal to the actuators. Furthermore, it shall initiate and execute the monitored parameters transmitted to the cloud storage.

System Design Blocks

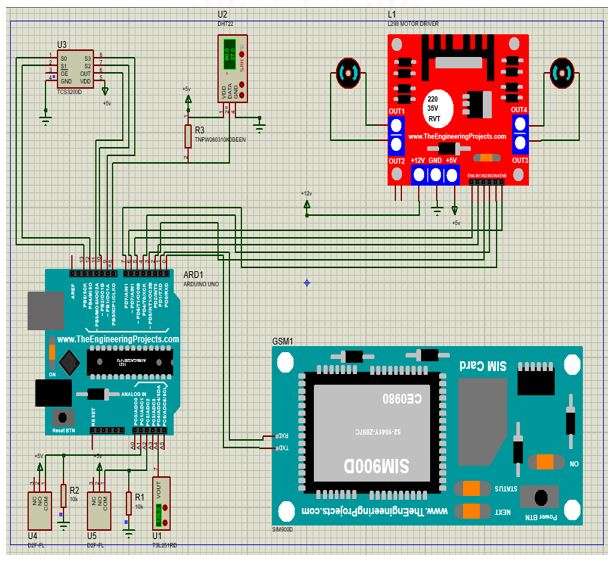

Each component used in this circuit, including the sensors, processor, actuator, and network transmission module, are modeled individually using Proteus 8 simulation software. All the components are modeled individually to compare their performance with the Arduino Uno on the Proteus 8 simulator. In each group, the circuits are compared before prototyping, and after this, measurements are taken. After that, equivalent circuit models are obtained from the Proteus 8 simulator. With the described model, the overall circuit characteristics are obtained. This is achieved by re-simulating the circuit with the C++ programming sketch code written on Arduino IDE.

Circuit Connection

Four sensors, two actuators, and network transmission component devices are selected for the implementation. The temperature and humidity sensing component using DHT22 was implemented Illuminance sensing using a Light-dependent resistor (LDR) was implemented. Color sensing using TCS3200 was implemented. The robot movement control using the limit switch sensor was implemented. The motor driver controlled the DC motor and was implemented. And the network transmission using the GSM module was implemented.

The Arduino Uno R3 has 14 digital input and output pins and six analogue pins. The pins D1 and D0 are reserved for transmitting (Tx) and receiving (Rx) connections, respectively, using the software serial. The D2 to D13 pins are used for the other hardware.

The cleaning robot has a balanced design, which increases its stability on a tilted solar panel. The robotic side panels are designed to ensure that the robot is guided along with the panels while cleaning. The cleaning system incorporates brushes, wheels, motors, connecting rods, side panels, wheel driving, and brush driving systems.

A motor-driven roller was considered to pull the system along the aluminum rail. The system could move along the panel without falling off with this design. The cleaning robot is powered by an electric motor that supplies the mechanical energy on the solar panel. Parallel rollers are mounted on the rail to move in the desired direction using the motor drive. Rotating the rollers in either direction moves the solar panel cleaning system to the desired location. The axles of the rollers and the brush run parallel to one another.

The data sent to the Thingspeak server will store in channels; that is, web servers receive data sent by GSM modules and post them to various channels after processing the data. The number of channels depends on the number of sensor types used in the system.

Signing up for a Thingspeak account is the first step. Then new channels are established and configured; afterward, an API key is generated. Programming modifications and data settings require the API key. The program codes are written to send data through the SIM900 GSM module to a web server from an Arduino Uno microcontroller