Today’s modern society is engaged with technology but fashion also plays a key role in our present generation. We live in a mad world were people are fond towards adorable things. This potty action can be terminated by bridging a gap between classic and crazy world. Even though India has modern cultural habits, the richness of Indian culture is what keeps people together. One of the long-term hobby of girls is MEHNDI. Even though regular usage of mehndi is not possible in their occupied life, they would definitely like to have mehndi on cultural occasions. But ongoing state-of-art is hand-operated which takes tons of seconds and manpower which has made people away from that interesting things. Mehndi designing cannot be done by everyone, only skilled person can make your hand a masterpiece. Even though girls are fond of designing their hands, due to lack of skill, they are depending on specialized person. As this process is done with care and passion, it takes much time to complete. To overcome this thing, we propose Smart Mehndi Artist , an mehndi automation machine which can instantly design our hand with any type of design that we love to have it in our fist. This product can eventually reduce the human efforts, time consumption, human errors and the cost paid for skilled persons. Also, this automation gives a comeback of ethical style through easy implementation for beauticians and customers.

This machine will include a stencil to keep one’s hand and a moving mehndi cartridge above the

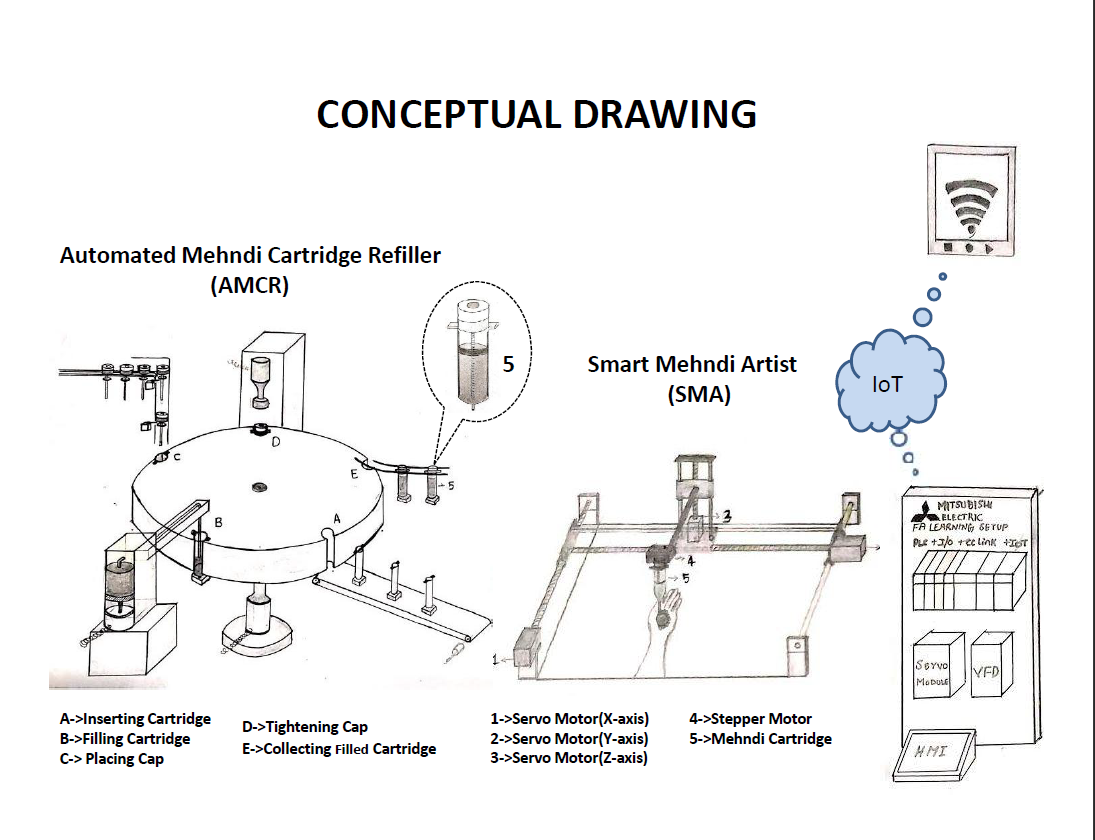

hand to apply Mehndi. A Proximity sensor and a scanner will be there to scan the image of hand and feed it to them through mobile application to recognize it. Then the image is worked out by the application and template of Mehndi design is adjusted according over the scanned image of hand. The mehndi design is feed through an mobile application using IIOT technology. The motion of mehndi cartridge is controlled by 3 servo motors which moves along x-axis, y-axis and z-axis. There will be a control mechanism to control the ejection of the Mehndi as per the requirement of design. It is used to stop the output when part of hand ends. This is done to ensure that there is no wastage of Mehndi. The machine will also be containing a sensor to stop Mehndi ejection when part of hand ends. This is to avoid the wastage of Mehndi. In future, we are planning to introduce a technique called AMCR(Automated Mehndi Cartridge Refiller).

PROJECT BUILDING IN SIMPLE STEPS

Step 1:(Hardware Setup)

The Smart mehndi artist machine will include a stencil to keep one’s hand and a moving arm of machine above the hand to apply Mehndi. An IIOT based mobile application will be there to scan the image of hand and feed it to the computer PLC software to recognize it.

Step 2:

Then the image is worked out by the software and template of Mehndi design is adjusted according over the image of hand. Thus nozzle can move over the hand accordingly fed by computer to draw the design.

Step 3:

Motion is controlled by a servo motored robotic arm. The beam is placed above the table, which guides the Mehndi cartridge moves along the length of, and the beam moves along stencil length, allowing for X- and Y-axis motion which is controlled by a Stepper motor.

Step 4:

Machine will use vector graphics to draw Mehndi art. A vaccum system is used to slightly grip the hand and the mechanism follows that there are small holes all over the stencil every will be connected to the vacuum pump. This vacuum pump will create a mild suction force which will grip the hand to the stencil so that any motion of hand can be constrained to ensure proper drawing of design over the hand. This vacuum pump will come into action as soon as it detects that hand is over the stencil using Proximity sensors.

step 5:

There will be a control mechanism which is programmed to control the ejection of the Mehndi as per the requirement of design. It is used to stop the output when part of hand ends. The machine will also be containing an proximity sensor to stop Mehndi ejection when part of hand ends. This is done to ensure that there is no wastage of Mehndi.

step 6:

This sensor will be an optical encoder to encode the data and fed it to computer so that computer may know when the part of hand ends. When the moving cone comes to the end of the hand while applying Mehndi over the hand then suddenly the Mehndi will be stopped coming out of the cone.

The cone or nozzle part from where the Mehndi is coming is programmed for up and down

movement also for complex designs so if by mistake it touches the hand and before going further

downwards it will stop. There is a Sensor equipped to stop down coming of nozzle when it

touches hand.

step 7:

Computer software will be used to control a Mehndi machine. PLC software can help design what needs to be drawn on the hand, using a computer . The machine have Read Only Memory (ROM) that allows the motions of the nozzle and arm to be programmed by the user.

step 8: (Software Setup)

There will be a provision to add new design into the Mobile App by using insert new design button.

The new design will be scanned by the Mobile camera which is transmitted via wi-fi based IIOT technology and here the PLC software will check for whether the design can be made with the machine or not. Feasibility of design will be checked by the software, that whether the design chosen to apply over the hand is feasible to be made by the machine or not.

Step 9:

PLC software will control when the flow of the Mehndi needs to come out of nozzle and when to stop

it according to the selected designs or templates. Size of hand recognition will also be done by software as soon as the scanned image is received from the Mobile app.

Step 10:

When the scanned image of the hand will be fed to computer by the app through IIOT then the selected

design will be made to fit over the hand and dimensions of the template will be resized according

to the dimensions of the hand.

Step 11:

Any new design if selected will also be resized according the templates as they get adjusted for the

palm of the hand.