Problem Statement

Floating bottles, plastic bags and even toys have become a part of the marine environment in recent times. Pitiful photographs of such plastic debris washed ashore on remote shorelines have frequently made headlines.

Most of this plastic pollution is attributed to an increase in tourism, shipping and fishing activities. But according to a recent study, a considerable portion of plastic garbage afloat in the open waters originates on land, and is drained into the seas by rivers.

But this is not just about the environment and the wildlife that live underwater—aquatic pollution affects everything from species, ecosystems, human health, coastal tourism, and contributes to climate change.

Our Solution

'The floating water waste extractor' used for the removal of waste debris in water bodies.

This machine architecture consists of a cleaner mechanism for the collection and removing waste from water bodies.

System consist of mechanism for lifting waste debris from the surface of water bodies. It consists of belt driver mechanism.

This is remotely controlled machine.

Design:

- The conveyor belt mechanism is used to which lifts the debris from the water.

- Propellers are used for driving mechanism of robot on the water.

- A basket is used for collection of waste,garbage etc.

- PVC pipes are used for the chassis of the robot because it has low weight and low cost.

The use of this project will made in ponds, lakes and other water bodies for cleaning upper water waste debris.

Block Diagram

.png)

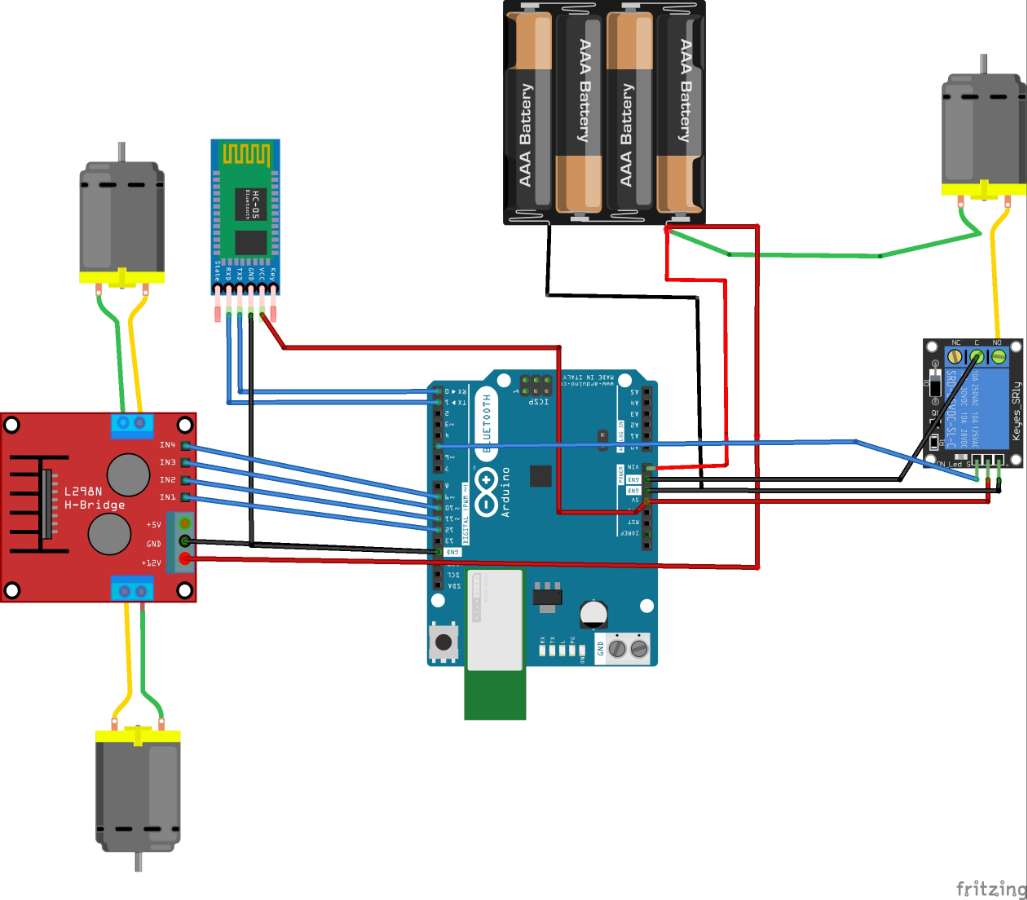

Connections

Make connections as per above diagram and upload the code in the microcontroller which is attached at the end the article.

- Connect Tx pin of arduino to Rx pin of HC-05

- Connect Rx pin of arduino to Tx pin of HC-05

- Connect 9,10,11,12 pins of arduino to IN4,IN3,IN2,IN1 of L298n motor driver respectively..

- Connect pin 5 of arduino to signal pin of relay.

Methodology

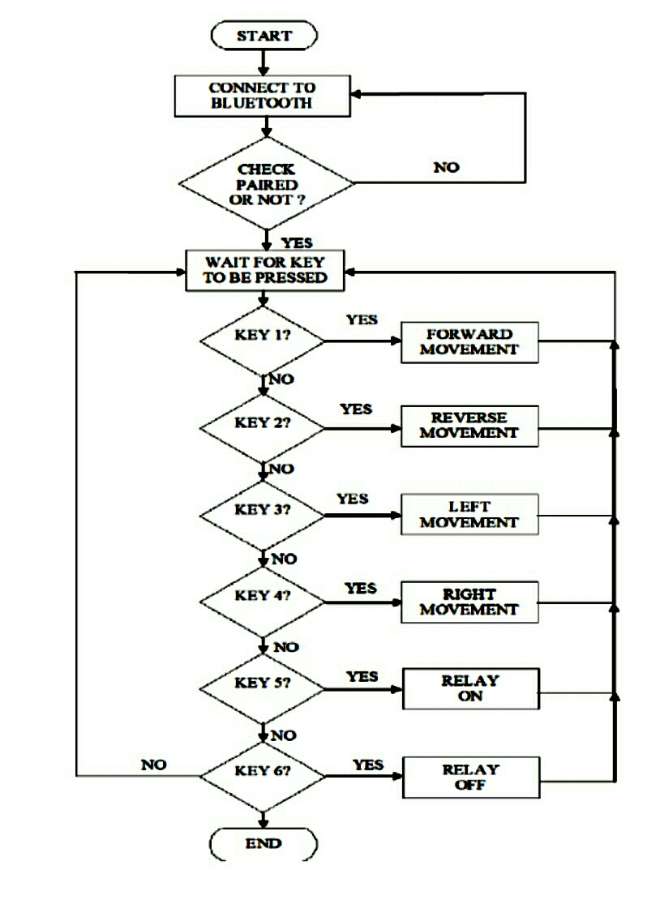

1. Switch On the device with the help of toggle switch.

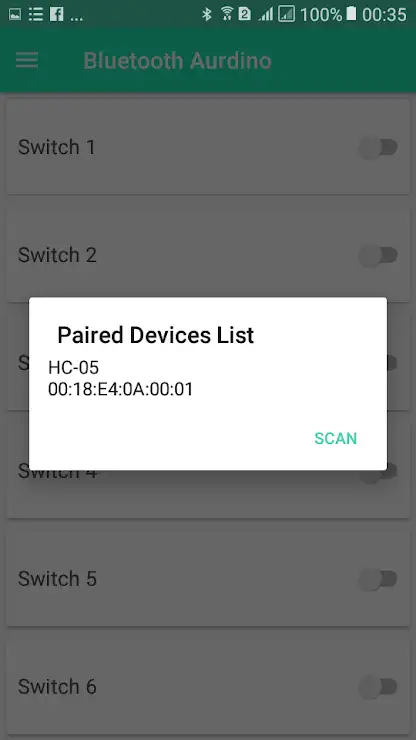

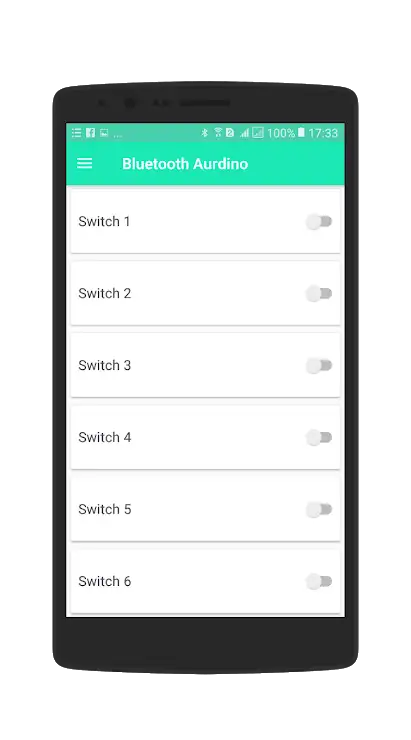

2. (i)Bluetooth module and smartphone are paired for navigation purpose.

(ii)Install this (https://play.google.com/store/apps/details?id=codetivelab.bluetoothaurdino&hl=en) application from play store.

Note : Default Bluetooth name of the device is “HC-05” and default PIN (password) for connection is either “0000” or “1234”.

3. Six keys are used to navigate the project key1 (forward), key2(Reverse), key3 (left), key4 (Right), key5 (relay on), key6 (relay off).

4. Robot is moved in forward and reverse direction with the help of propellers and can also be turned around by using navigation keys i.e.(Right/Left)

5. Waste from water bodies is collected with the help of conveyor mechanism which is operated with the help of relay by using 5th and 6th navigating key.

6. Collected garbage is stored in the basket.

7. Once the basket is full it should be emptied manually and Water-Sharkis made to repeat the same action for collecting garbage.

Video

Future Prospects

In future we are going to try autonomous version that will swim around according to waypoints that you give it. There would be sensors like ultrasonic sensor to detect the presence of wall . System would be designed to detect hardness of water by using sensors and by spraying the chemicals wherever needed, water is made soft and germs free, so that it will help to reduce water born diseases to a certain extent.

Code

#define relay 5

#define interval 5000

char t;

void setup()

{

pinMode(9,OUTPUT); //left motors forward

pinMode(10,OUTPUT); //left motors reverse

pinMode(11,OUTPUT); //right motors forward

pinMode(12,OUTPUT); //right motors reverse

pinMode(relay,OUTPUT); //relay

Serial.begin(9600);

}

void loop() {

if(Serial.available())

{

t = Serial.read();

Serial.println(t);

}

if(t == '1') //move forward(all motors rotate in forward direction)

{

digitalWrite(12,HIGH);

digitalWrite(11,LOW);

digitalWrite(10,HIGH);

digitalWrite(9,LOW);

Serial.println("forward");

}

else if(t == '2') //move reverse (all motors rotate in reverse direction)

{

digitalWrite(12,LOW);

digitalWrite(11,HIGH);

digitalWrite(10,LOW);

digitalWrite(9,HIGH);

Serial.println("reverse");

}

else if(t == '3') //turn right (left side motors rotate in forward direction, right side motors doesn't rotate)

{

digitalWrite(12,LOW);

digitalWrite(11,LOW);

digitalWrite(10,HIGH);

digitalWrite(9,LOW);

Serial.println("left");

}

else if(t == '4') //turn left (right side motors rotate in forward direction, left side motors doesn't rotate)

{

digitalWrite(12,HIGH);

digitalWrite(11,LOW);

digitalWrite(10,LOW);

digitalWrite(9,LOW);

Serial.println("right");

}

else if(t == '5') //relay On

{

digitalWrite(relay,HIGH);

Serial.println("relay ON");

delay(interval);

}

else if (t =='6') //relay Off

{

digitalWrite(relay,LOW);

Serial.println("relay OFF");

delay(interval);

}

}