Phase 1: Design and Planning

Step 1: Create the Chassis Frame

Start by designing a robust chassis that can support both land and water operations. The frame serves as the backbone for all components.

Materials Needed:

Acrylic sheets (6mm thick) or plywood for the main platform

PVC pipes (20mm diameter) for structural support

Aluminum extrusions for reinforcement

Stainless steel screws and bolts.

Construction Process:

Cut two rectangular chassis plates (370mm x 400mm) with U-shaped openings for the collection mechanism

Create mounting holes for motors, sensors, and electronic components

Connect the chassis plates using PVC pipes or aluminum extrusions as spacers

Ensure the frame is lightweight yet durable enough to handle water conditions.

Step 2: Design the Buoyancy System

For water operation, the robot needs proper flotation. This is achieved through pontoons or sealed chambers.

Pontoon Construction:

Use sealed PVC tubes or custom-made fiberglass pontoons

Calculate buoyancy: ensure the robot's total weight is less than the water displacement

Attach pontoons to the sides of the main chassis.

Apply waterproof sealant at all connection points.

Phase 2: Electronics and Control System

Step 3: Assemble the Control Electronics

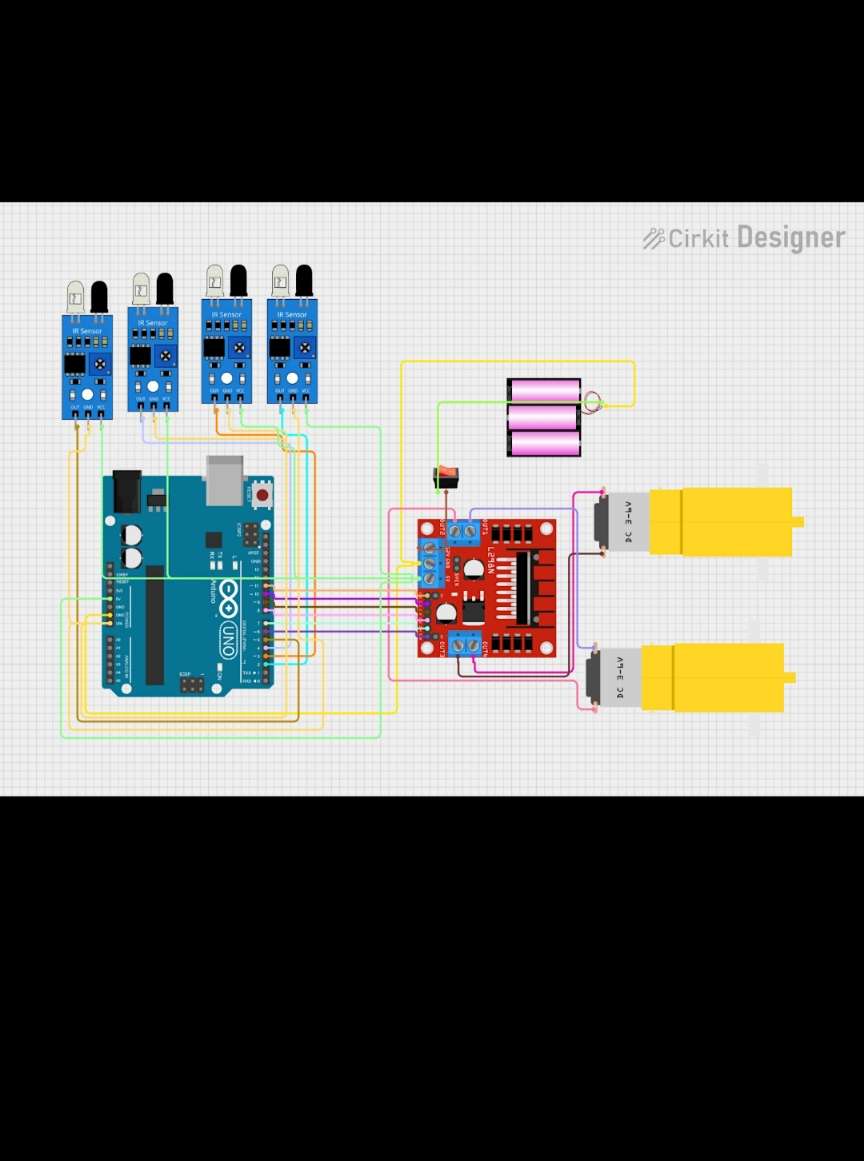

The brain of the robot consists of microcontrollers and motor drivers that coordinate all operations.

Core components

urdino UNO as the main controller

L298N motor driver for controlling DC motors

Battery pack (12V lithium-ion recommended)

Voltage regulator (LM2596) for stable power supply.

Wiring Configuration:

Connect the aurdino UNO to the motor driver's input pins

Wire the battery pack to the motor driver's power input

Connect motors to the motor driver outputs

Add a power switch and LED indicators for system status

Step 4: Install Sensors and Navigation

Multiple sensors enable autonomous operation and obstacle detection.

Sensor Setup:

Ultrasonic sensors (HC-SR04): Mount on front and sides for obstacle detection

Camera module (ESP32-CAM): Install for real-time monitoring and waste detection

GPS module: Add for autonomous navigation (optional)

Waterproof sensors: Use A02YYUW waterproof ultrasonic sensors for water operation

Waterproofing Techniques:

Seal all electronic connections with marine-grade silicone

Use IP67-rated enclosures for critical components

Apply conformal coating to circuit boards for moisture protection

Phase 3: Mechanical Systems

Step 5: Build the Waste Collection Mechanism

The conveyor belt system is crucial for effective garbage collection.

Conveyor Assembly:

Create a frame using PVC pipes or aluminum channels

Install a rubber conveyor belt with appropriate width (150-200mm)

Mount stepper motors at both ends for belt drive

Add a collection bin behind the conveyor system

Include a cutting mechanism for larger debris (optional)

Belt Configuration:

Use food-grade rubber belting for durability

Add cleats or texture for better waste grip

Ensure proper tension adjustment mechanisms

Step 6: Install the Propulsion System

Different propulsion methods are needed for land and water operation.

Land Operation:

Mount four DC gear motors with wheels for ground mobility

Use treaded wheels for better traction on various surfaces

Install a steering servo for directional control

Water Operation:

Add waterproof thrusters or propellers for water propulsion

Mount brushless motors that don't require additional waterproofing

Configure thrust vectoring for omnidirectional movement

Phase 4: Programming and Control

Step 7: Develop the Control Software

The software coordinates all robot functions and enables remote operation

Control Features:

Manual remote control via smartphone app

Automatic obstacle avoidance

GPS waypoint navigation (advanced feature)

Real-time video streaming from onboard camera

Step 8: Create the User Interface

Develop a mobile application for remote operation and monitoring.

App Features:

Live camera feed display

Manual control buttons (forward, backward, turn)

Waypoint setting for autonomous operation

Battery level and system status indicators

Emergency stop function

Phase 5: Testing and Optimization

Step 9: Conduct System Tests

Land Testing:

Test basic mobility on various terrains

Verify obstacle detection and avoidance

Test garbage collection efficiency with different waste types

Check battery life during continuous operation

Water Testing:

Verify buoyancy and stability in calm water

Test propulsion system effectiveness

Check waterproofing integrity of all components

Evaluate collection mechanism performance with floating debris