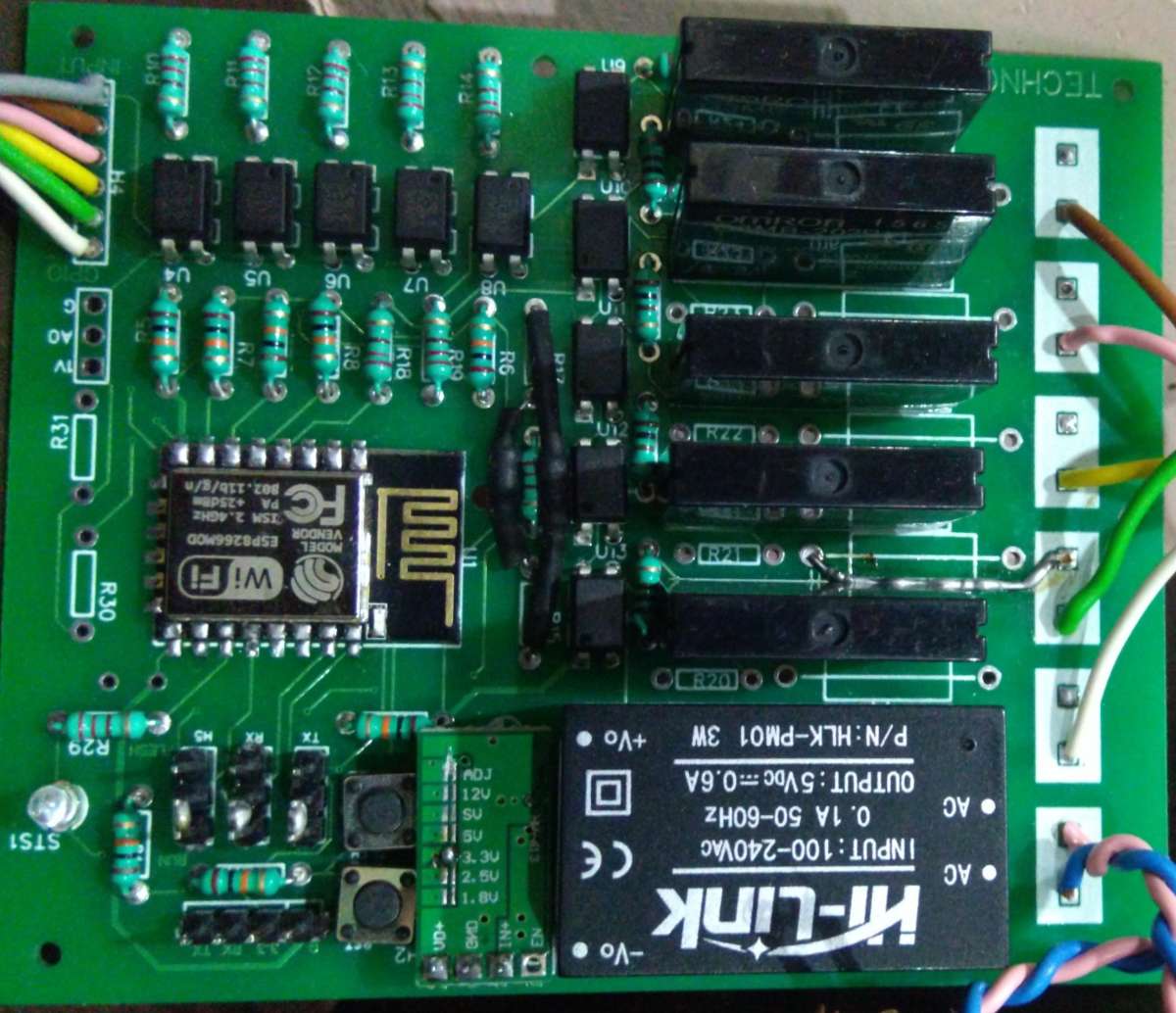

TECHSWTCH 1.0 an OpenSource Smart Switch Hardware (5Cannel)

TECHSWITCH 1.0 PLB Layout

Introduction Video of TechSwitch 1.0

Empower Smart home by TechSwitch-1.0(DIY Mode) .

- What is TechSwitch-1.0(DIY Mode)

- TechSwitch-1.0 is ESP8266 based smart switch. it can control 5 home appliances.

- Why it is DIY mode??

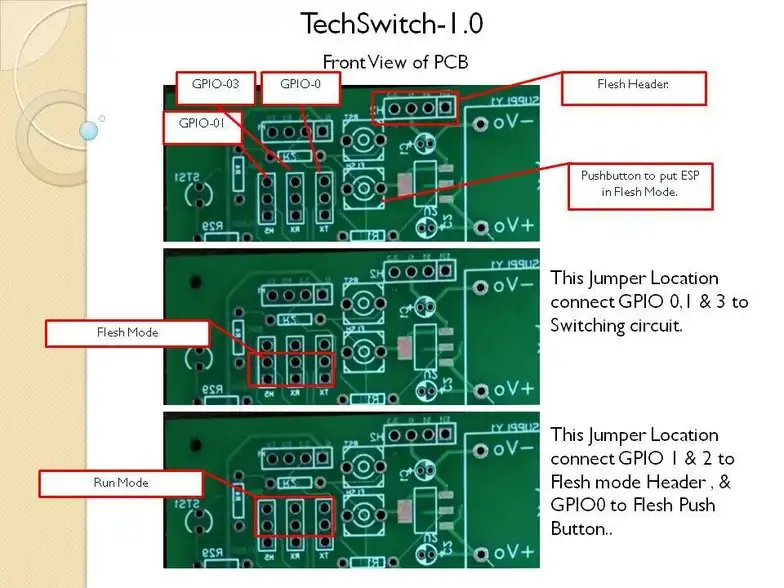

- It is designed to re-flash at any time. there is two mode selection jumper on PCB.

- Run Mode:- for Regular operation.

- Flash Mode :- in this mode user can re-flash chip by following Re-flash procedure.

- Analog Input:- ESP8266 has one ADC 0-1 Vdc. Its header also provided on PCB to play with any Analog sensor.

- It is designed to re-flash at any time. there is two mode selection jumper on PCB.

Technical Specification of TechSwitch-1.0(DIY mode)

- 5 Output(230V AC) + 5 Input(0VDC switching) + 1 Analog input(0-1VDC)

- Rating :- 2.0 Amps.

- Switching element :-- SSR +Zero Crossing switching.

- Protection :- Each output protected by 2 Amp. glass fuse.

- Firmware used:- Tasmota is easy to use and stable firmware. It can be flashed by different firmware as its DIY mode.

- Input :- Opto coupled (-Ve) switching.

- ESP8266 power regulator can be dual mode:- can use Buck converter as well AMS1117 regulator.

Supplies/Bill Of material

- Power Supply:- Make :- Hi-Link , Model :- HLK-PM01, 230V by 5 VDC, 3W (01)

- Microcontroller:- ESP12F (01)

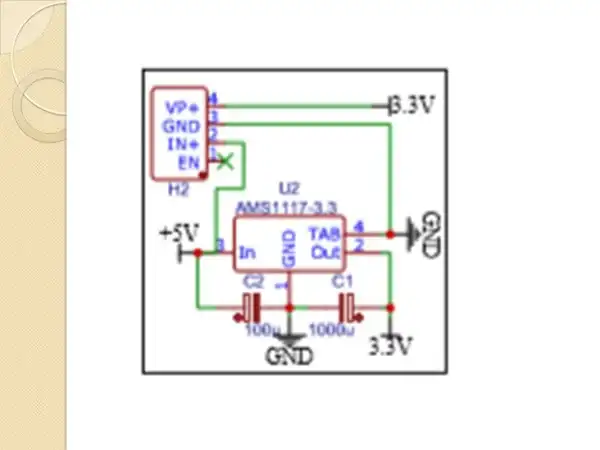

- 3.3 VDC regulator :- Dual provision any one can be used

- Buck converter (01)

- AMS1117 Voltage regulator.(01)

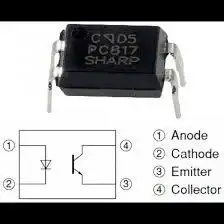

- PC817 :- Opt coupler Make :- Sharp Package:-THT (10)

- G3MB-202PL:- SSR Make Omron(05), Zero crossing switching.

- LED :-Color:- Any, Package THT (01)

- 220 or 250 Ohm Resistor:- Ceramic (11)

- 100 Ohm Resistor:- Ceramic (5)

- 8k Ohm Resistor :- Ceramic(1)

- 2k2 Ohm Resistor :- Ceramic(1)

- 10K Ohm Resistor:- Ceramic (13)

- Push button :-Part Code:- EVQ22705R, Type:- with Two terminal (02)

- Glass Fuse:- Type :- Glass, Rating :- 2 Amp @ 230V AC. (5)

PCB Male Header:- Three header with Three pin & One header with 4 Pin. so one standard Strip of Male header is preferable to procure.

Designing & Selection of componant Process/Methdology

Step 1: Consept Finalization.

- Finalization of Concept:- I have define requirement as below.

- Making Smart Switch having 5 Switch & Can controlled by WIFI.

- It Can operate withot WIFI by physical Switches or Pushbutton.

- Switch can be DIY mode so it can be RE-Flashed.

- It can fit in existing switch board without changing any switches or wiring.

- ALL GPIO of Microcontroller to be used as it is DIY mode.

- Switching device should SSR & zero crossing to avoide noice & switching surges.

- Size of PCB Should be small enough so it can fit in existing switchboard.

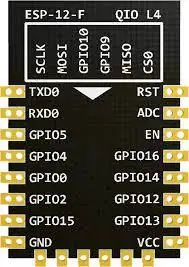

Step 2: Selection of Microcontroller

- As we finalized requirement , next step is to select hardware

- Microcontroller selection criteria.

- Required GPIO :-5 input + 5 Output + 1 ADC.

- Wifi enabled

- Easy to Re-flash to provide DIY functionality.

- Mqtt Support

- HTTP Support

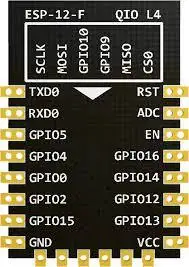

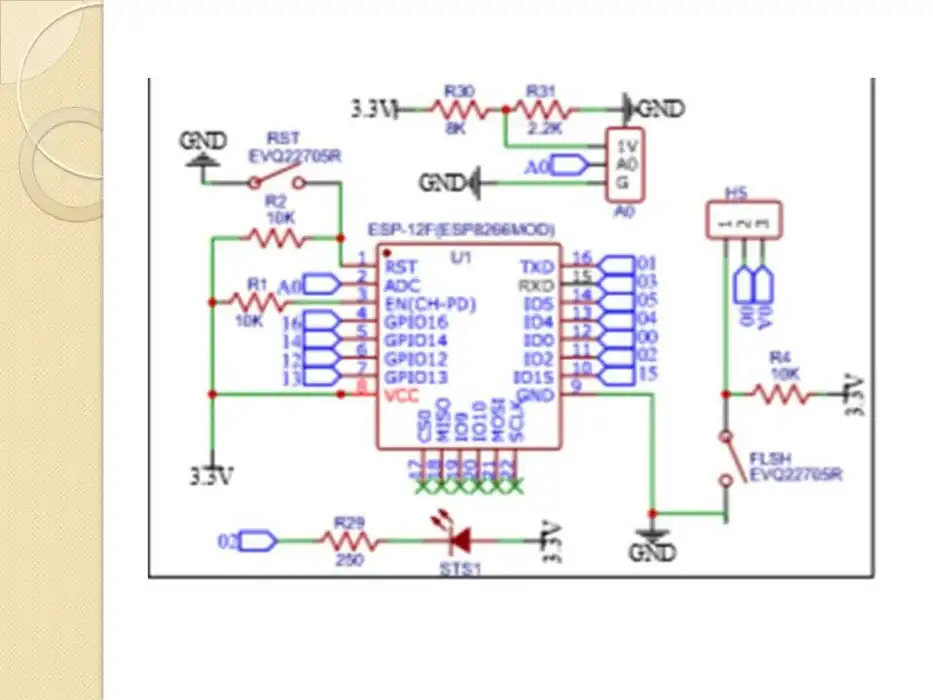

ESP8266 is suitable for above requriement. it has 11 GPIO + 1 ADC + WiFi enabled.

I have selected ESP12F module which is ESP8266 microcontroller based Devlopment board , it has small formfactor & all GPIO are populated for easy use.

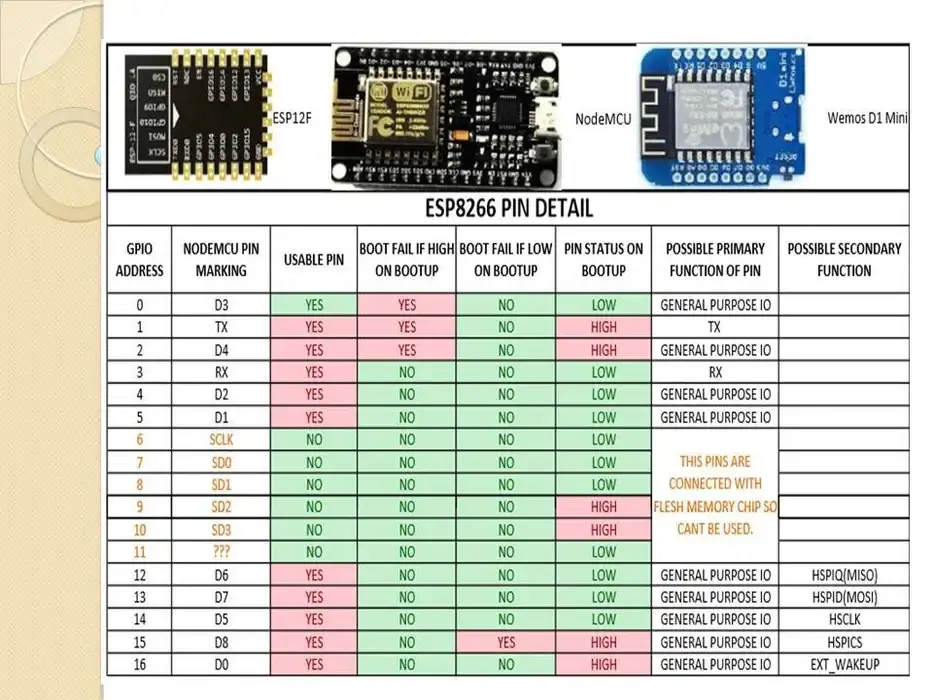

Step 3: Checking GPIO Detail of ESP8266 Board.

Below is GPIO detail of ESP8266 which used to select appropriate GPIO for Input or Output functionality.

- As per ESP8266 Data sheet some GPIO are used for special functions.

- During Breadboard Trial, I scratched my head as not able to boot it plenty of time.

- Finally by research on internet and playing it with breadboard I have summarized GPIO data and made simple table for easy understanding.

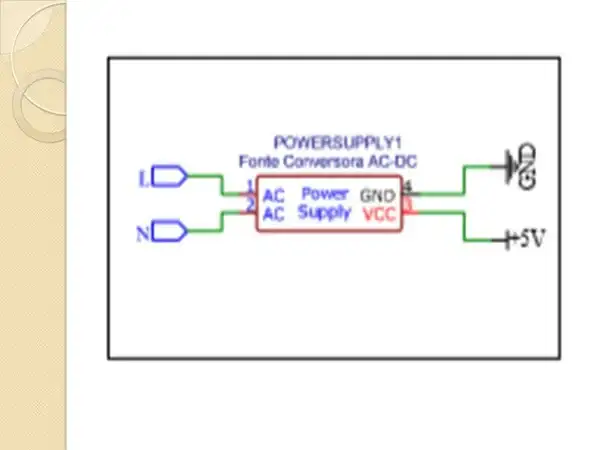

Step 4: Selection of Power Supply.

.webp)

.webp)

- Selection Criteria of Power Supply.

- In India 230VAC is domestic supply. as ESP8266 operates on 3.3VDC, we have to select 230VDC / 3.3VDC power supply.

- Power Switching device which is SSR which operates on 5VDC so i have to select Power Supply having 5VDC as well.

- Finally selected power supply having 230V/5VDC.

- To get 3.3VDC i have selected Buck converter having 5VDC/3.3VDC.

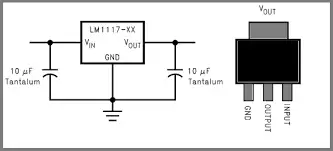

- As we have to design DIY mode i also provide provision of AMS1117 linear voltage regulator.

Final Conclusion.

- First power supply conversion is 230VAC / 5 VDC having 3W capacity.

- HI-LINK make HLK-PM01 smps.

- Second conversion is 5VDC to 3.3VDC

- For this i have selected 5V/3.3V Buck converter.

- i have also kept provision of AMS1117 Linear voltage regulator on PCB so we can use any one which is easily available.

- PCB made in such way it can use AMS1117 or buck converter(Anyone one).

- IF AMS1117 Used then we have to use capacitor for to improve voltage stability.

- Schematic detail is mentioned in schematic explanation section below.

Step 5: Selection of Switching Device.

- I have selected Omron Make G3MB-202P SSR

- SSR having 2 amp. current capacity.

- Can operates on 5VDC.

- Provide Zero crossing Switching.

- Inbuilt Snubber circuit.

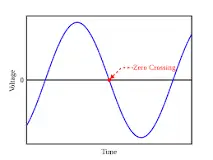

What is Zero Crossing?

- 50 HZ AC supply is sinusoidal voltage.

- Supply voltage polarity changed every 20 mille second & 50 times in one second.

- Voltage gets zero every 20 mille second.

- Zero crossing SSR detects zero potential of voltage and turn on output on at this instance.

- For example :- if command send at 45 Degree (voltage at maximum peak), SSR turned on at 90 degree(when voltage is zero).

- This reduces switching surges & noise.

- Zero crossing point is shown in attached image (Red highlighted text)

Step 6: ESP8266 PIN Selection.

- ESP8266 has total 11 GPIO and One ADC pin. (Refer Step 3)

- PCB Pin identification

- Pin selection of esp8266 is crucial because of below criteria.

- Criteria for Input selection:-

- GPIO PIN15 Required to be Low during Bootup other wise ESP will not boot.

- It try to bootup from SD card if GPIO15 is High during Bootup.

- ESP8266 neve Boot If GPIO PIN1 or GPIO 2 or GPIO 3 is LOW during bootup.

- GPIO PIN15 Required to be Low during Bootup other wise ESP will not boot.

- Criteria for Output Selection :-

- GPIO PIN 1,2,15 & 16 get High during Bootup(for fraction of time).

- if we use this pin as input & PIN is at LOW level during bootup then this pin gets damaged due to short circuit between PIN which is Low but ESP8266 turin it HIGH during bootup.

- Final conclusion :-

- Finally GPIO 0,1,5,15 & 16 are selected for output.

- GPIO 3,4,12,13 & 14 are selected for Input.

- Criteria for Input selection:-

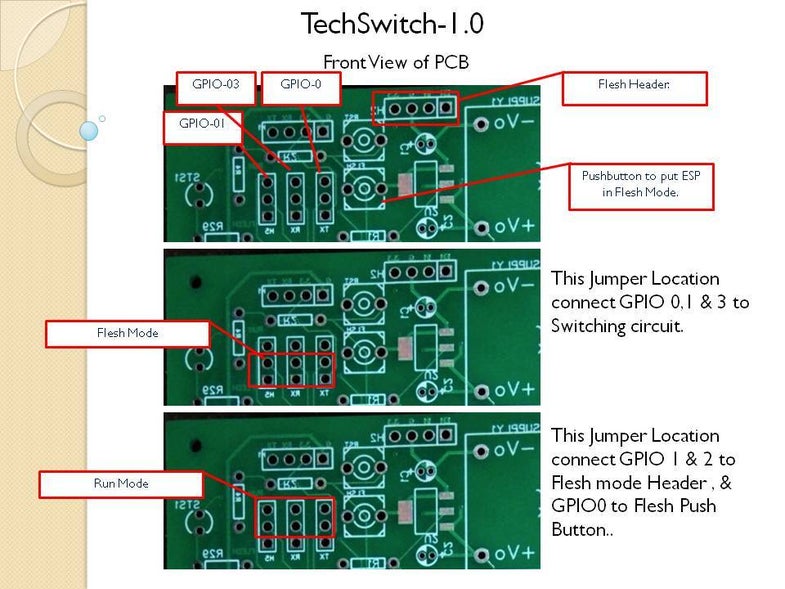

- Constrain:-

- GPIO1 & 3 is UART pins which are used to flash ESP8266 & we also wanted to use those as output.

- GPIO0 is used to put ESP in flash mode & we also decided to use it as output.

- Solution for above constrain:-

- Problem solved by provide two jumpers.

- Flash mode jumper: - In this position all three pins are isolated from switching circuit and connected to flash mode header.

- Run mode jumper:- In this position all three pins will connected to switching circuit.

Step 7: Optocoupler Selection.

- PIN Detail:-

- PIN 1 & 2 Input Side (Inbuilt LED)

- Pin 1 :- Anode

- Pnd 2 :- Cathode

- PIN 3 & 4 Output Side(Photo transistor.

- Pin 3:- Emitter

- Pin 4 :- Collector

- PIN 1 & 2 Input Side (Inbuilt LED)

- Output switching circuit selection

- ESP 8266 GPIO can feed only 20 m.a. as per esprissif.

- Optocoupler are used to protect ESP GPIO PIN during SSR switching.

- 200 Ohms resistor is used to limit current of GPIO.

- I have used 200, 220 & 250 & all resistors are work fine.

- Current calculation I = V/R, I = 3.3V - 0.7V / 200 Ohms = 13 ma.

.webp)

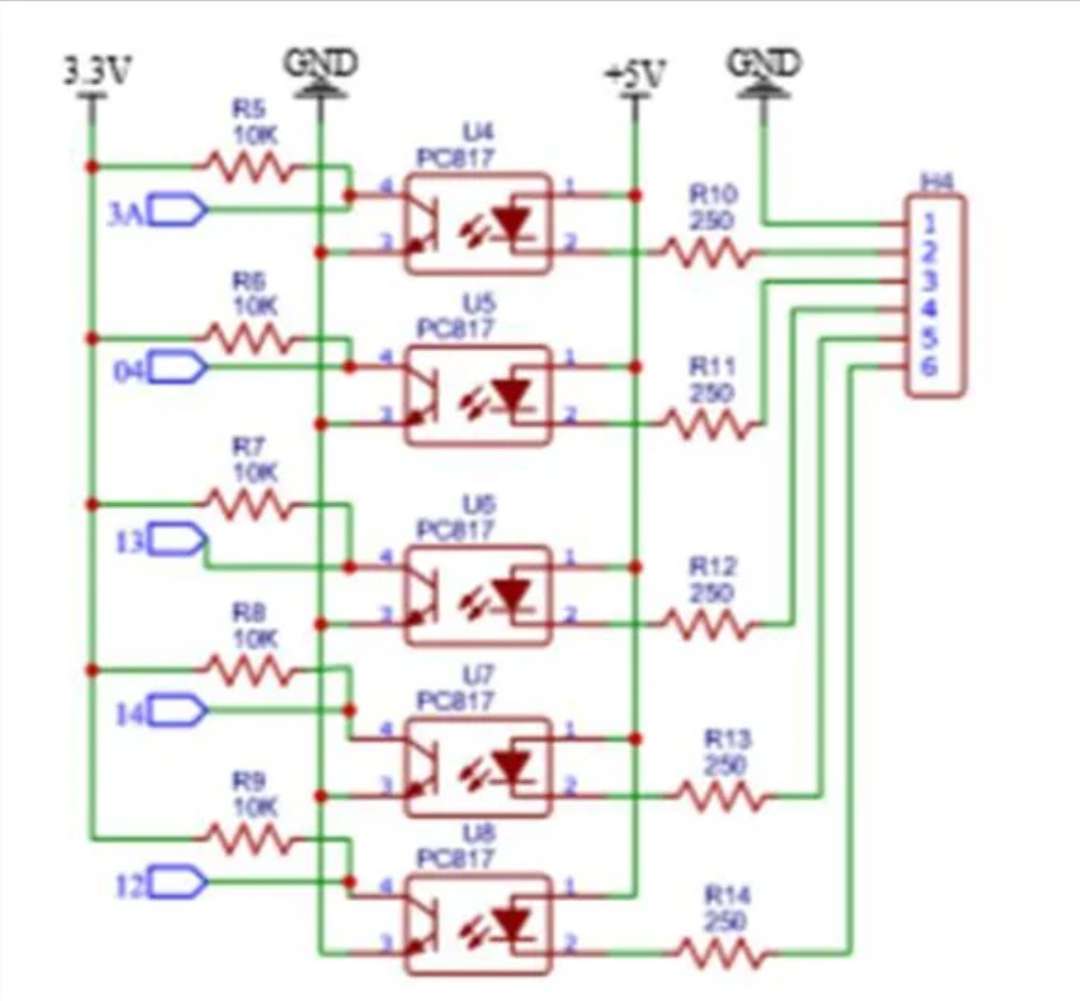

- Input Switching circuit selection.

- PC817 optocouplers are used in input circuit with 200 ohms current limiting resistor.

- Output of optocoupler are connected with GPIO (defined as Input) along with 10K Pull-up resistor as shown below.

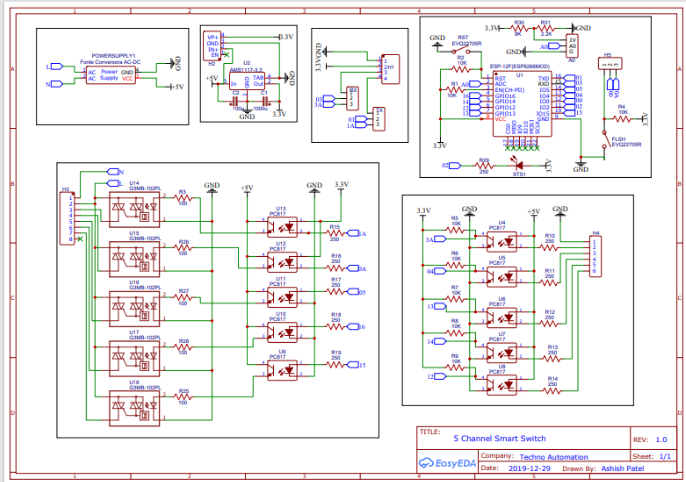

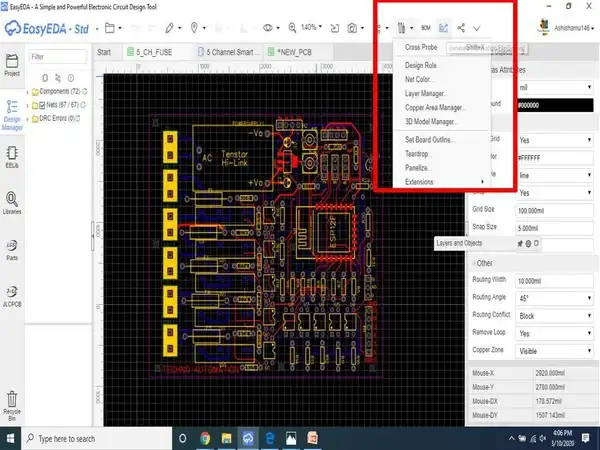

Step 8: Circuit Layout Preparation.

- After selection of all component and define wiring methodology, we can move on to develop Circuit using any pcb designing software.

- i have used Easyeda which is Web based PCB development platform and easy to use.

- URL of Easyeda :- EsasyEda

- For simple explainaiton i have divided whole circuit in chunks. & first is Power circuit.

- Power circuit A:- 230 VAC to 5VDC.

- HI-Link makes HLK-PM01 SMPS used to convert 230Vac to 5 V DC.

- Maximum Power is 3 Watt. means it can supply 600 ma.

- Power circuit A:- 230 VAC to 5VDC.

- Power circuit B:- 5VDC to 3.3VDC.

- As this PCB is DIY mode. i have provide two method to convert 5V to 3.3V.

- Using AMS1117 Voltage regulator.

- Using Buck Converter.

- Anyone can used as per component availability.

Step 9: ESP8266 Wiring

EasyEda used to design schematic of PCB & Net port option is used to make schematic simple.

What is Net port??

- Net post means we can provide name to common junction.

- by using same name in different part, Easyeda will considered all same name as single connected device.

Some basic rule of esp8266 wiring.

- CH_PD pin required to be high.

- Reset pin required to be high during normal operation.

- GPIO 0,1 & 2 shoud not at Low during boot up.

- GPIO 15 should not at High level during Boot up.

- Considering all above points in mind ESP8266 wiring scheme is prepared. & shown in schematic image as mentioned below.

- GPIO2 is used as Status LED & connected LED in Reverse polarity to avoide GPIO2 LOW.

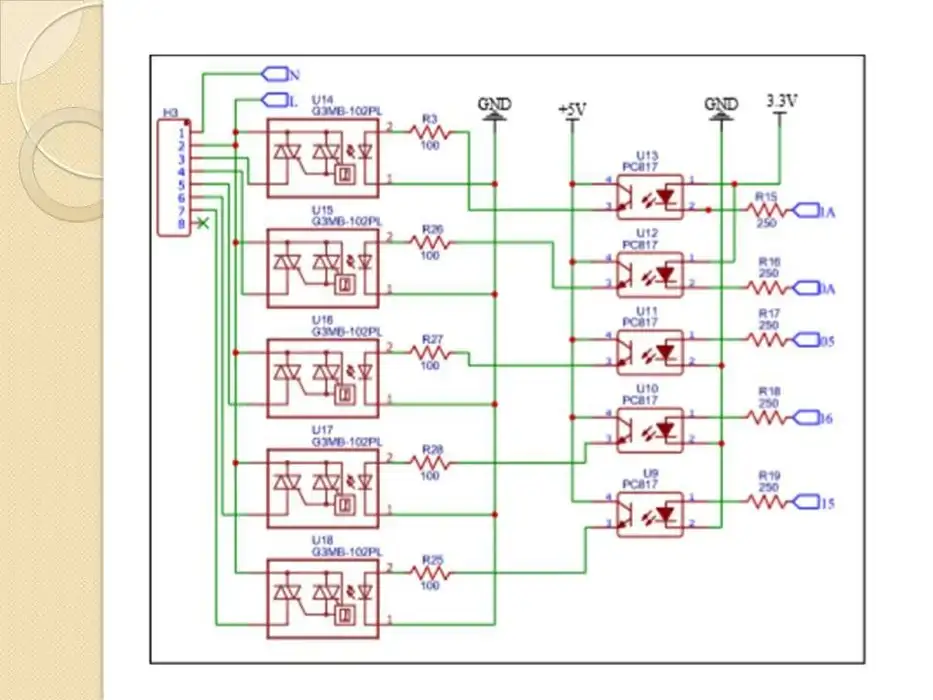

Step 10: ESP8266 Output Switching Circuit

- ESO8266 GPIO 0, 1, 5, 15 & 16 used as output.

- To keep GPIO 0 & 1 at high level its wiring is bit different from other output.

- Booth this pin is at 3.3V during boot up.

- PIN1 of PC817 which is anode is connected to 3.3V.

- PIN2 which is Cathode is connected to GPIO using current limiting resistor(200/220/250 Ohms).

- As forward biased Diode can pass 3.3V(0.7V diode drop) Both GPIO get almost 2.5 VDC during boot up.

- Remaining GPIO pin connected with PIN1 of pc817 which is Anode of PC817 & Ground is connected with PIN2 which is Cathode using current limiting resistor.

- As Ground is connected with Cathode it will pass from PC817 LED and keep GPIO at Low level.

- This makes GPIO15 LOW during boot up.

- We solved problem of all three GPIO by adopting different wiring scheam.

Step 11: Esp8266 Input.

- GPIO 3,4,12,13 & 14 are used as Input.

- As Input wiring will be connected to field device, protection required for ESP8266 GPIO.

- PC817 optocoupler used for input isolation.

- PC817 Input Cathodes are connected with Pin headers using current limiting resistor (250 Ohms).

- Anode of all Optocoupler is connected with 5VDC.

- Whenever Input pin connected to Ground, Optocoupler will get forward biased and output transistor turned on.

- Collector of optocoupler is connected with GPIO along with 10 K Pull-up resistor.

- What is Pull-up???

- Pull-up resistor is used To keep GPIO stable, high value resistor connected with GPIO and another end is connected to 3.3V.

- this keep GPIO at high level and avoid false triggering.

Step 12: Final Schematic

- Final Schematic is as below. After Completion of all parts its time to check wiring.

- Easyeda Provide feature for this.

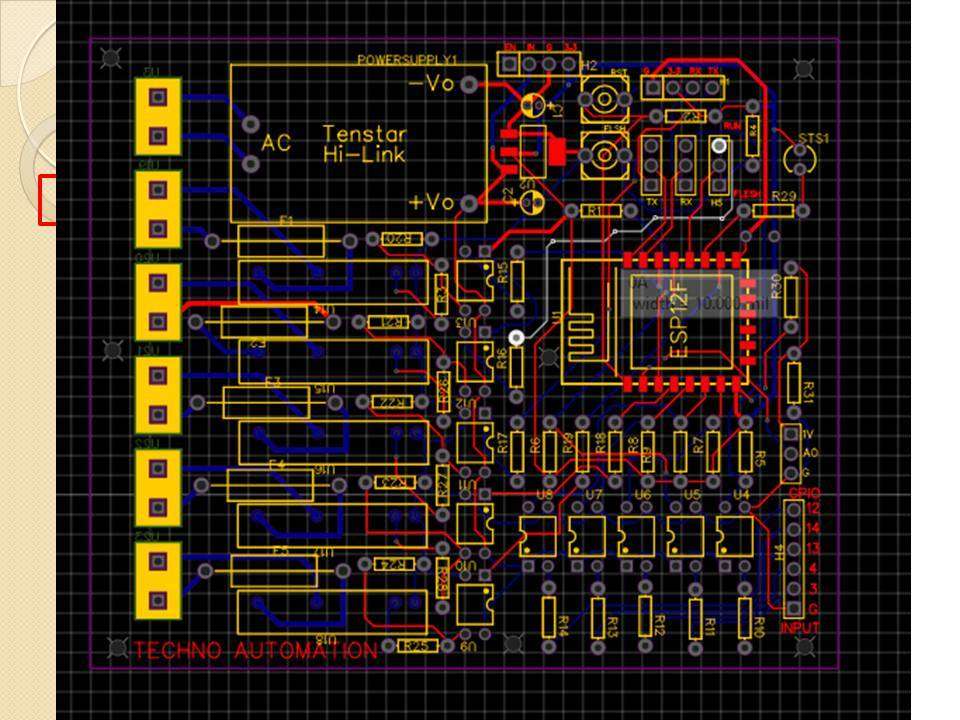

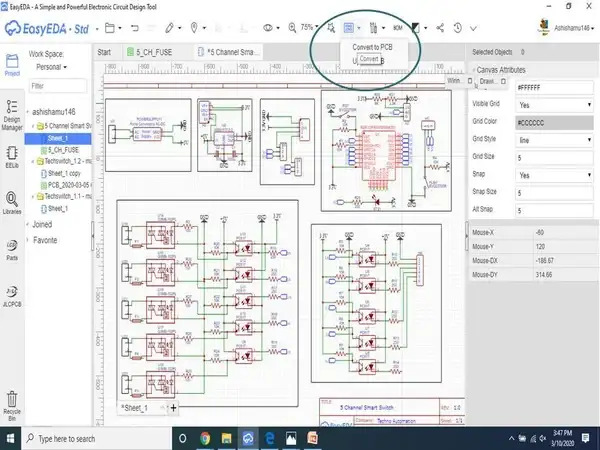

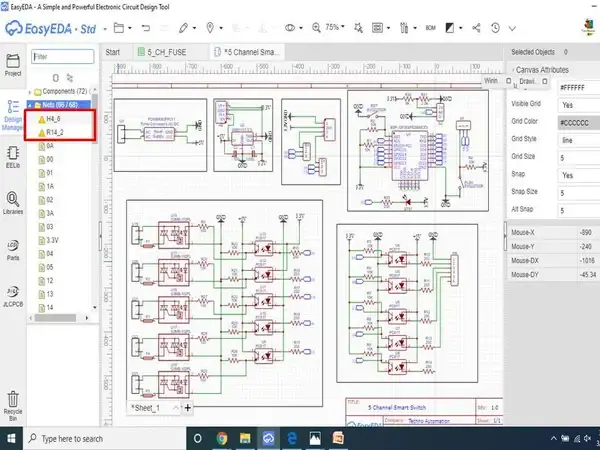

Step 13: Convert PCB

- Steps to convert Circuit in to PCB Layout

- After making Circuit we can convert it in to PCB layout.

- By pressing Convert to PCB option of Easyeda system will start conversion of Schematic in to PCB Layout.

- If any wiring error or unused pins are present then Error/Alarm generates.

- By checking Error in Right side section of Software development page we can resolve each error one by one.

- PCB layout generated after all error resolution.

- Steps to convert Circuit in to PCB Layout

- After making Circuit we can convert it in to PCB layout.

- By pressing Convert to PCB option of Easyeda system will start conversion of Schematic in to PCB Layout.

- If any wiring error or unused pins are present then Error/Alarm generates.

- By checking Error in Right side section of Software development page we can resolve each error one by one.

- PCB layout generated after all error resolution.

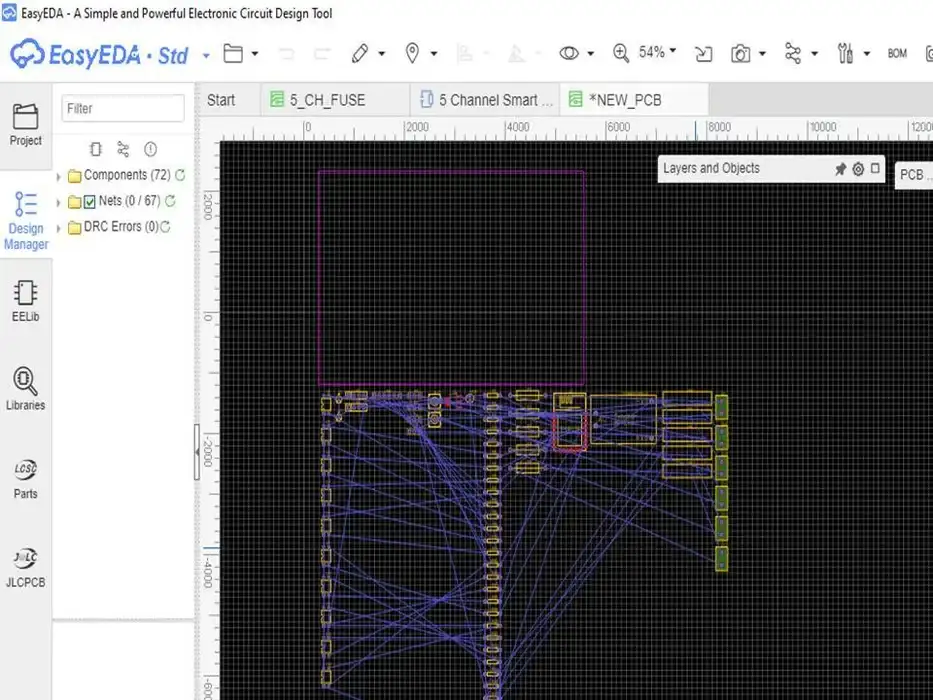

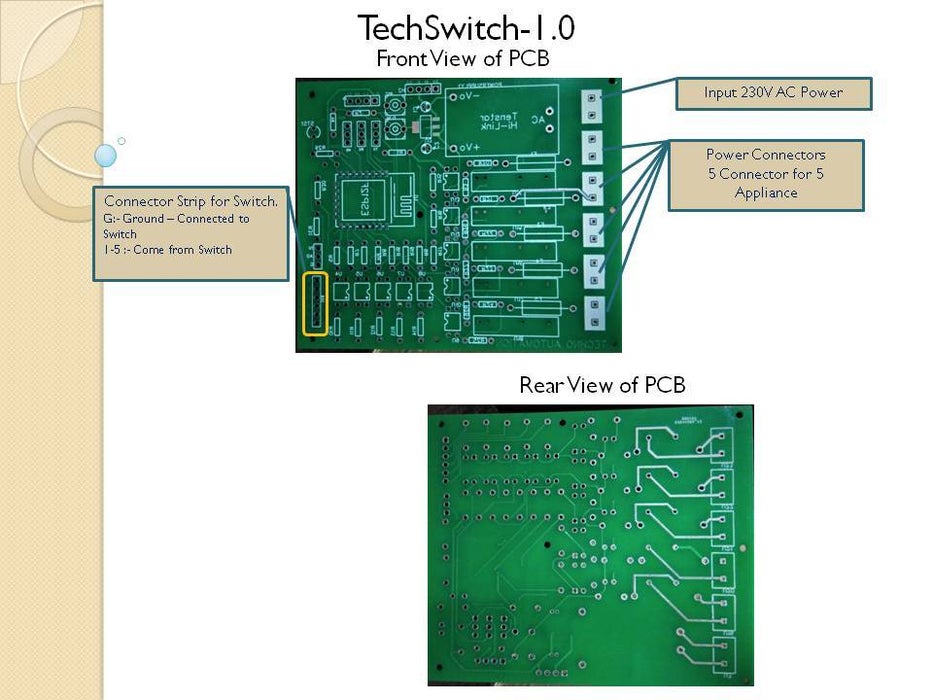

Step 14: PCB Layout & Componant Arrangement.

- Componant Placement

- All components with its actual

- dimensions and labels are shown in PCB layout screen.

- First step is to arrange component.

- Try to put High voltage and Low voltage component as far as possible.

- Adjust each component as per required size of PCB.

- After arranging all components we can make traces.

- (traces width required to be adjust as per current of circuit part)

- Some of traces are traced in bottom of pcb using layout change function.

- Power traces are keeping exposed for soldering pouring after fabrication.

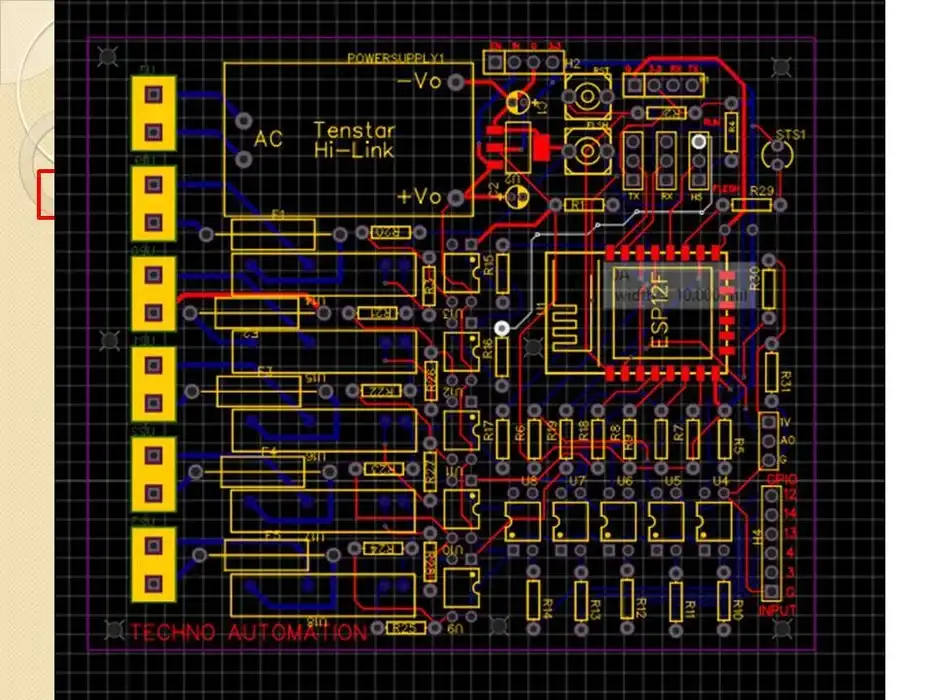

Step 15: Final PCB Layout.

- Finaliized all componant layout as shown below.

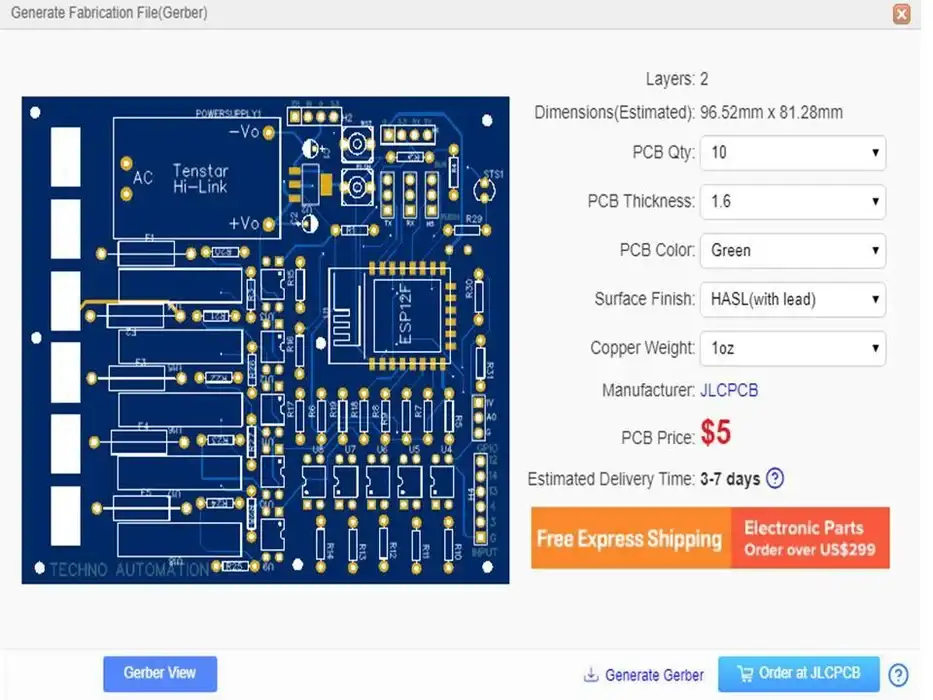

Step 16: Checking 3D View and Generating Ggerber File.

- Easyeda provide 3D view option in which we can check 3D view of PCB and get idea how it looks after fabrication.

.webp)

- After checking 3D view Generate Gerber files.

Step 17: Placing Order.

- After Generation of Gerber file system provides Front view of final PCB layout and cost of 10 PCB.

- We can place order to JLCPCB directly by pressing "Order at JLCPCB" Button.

- We can select color masking as per requirement and select mode of delivery.

- By placing order and making payment we get PCB within 15-20 days.

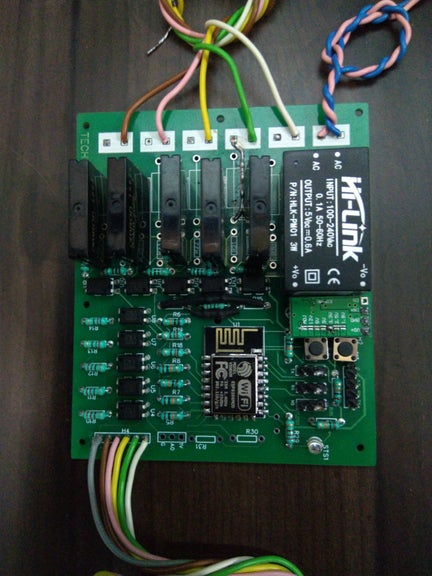

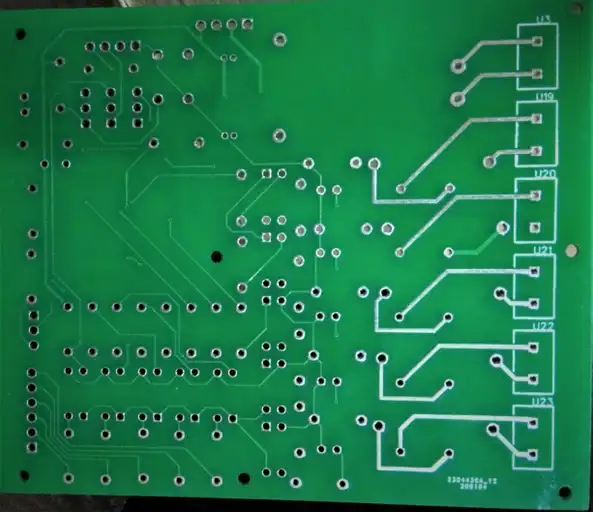

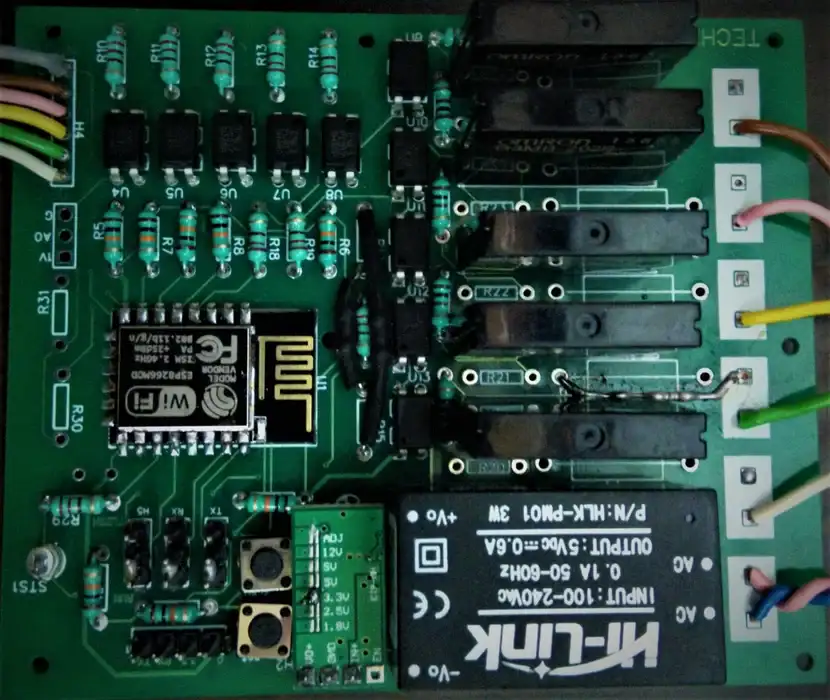

Step 18: Recieving PCB.

- Visually inspect PCB front and back after receiving it which looks good.

- Front side of PCB

.webp)

- Back Side of PCB

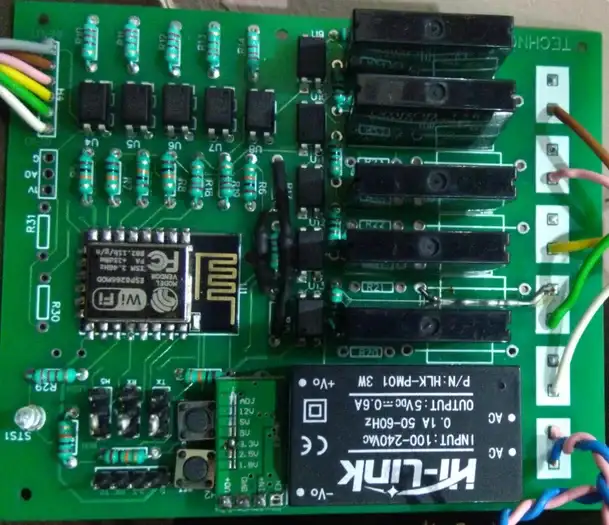

Step 19: Componant Soldring on PCB.

- As per component identification ON PCB all components soldering started.

- Take Care:- Some part footprint is backward side so check labeling on PCB and part manual before final soldering.

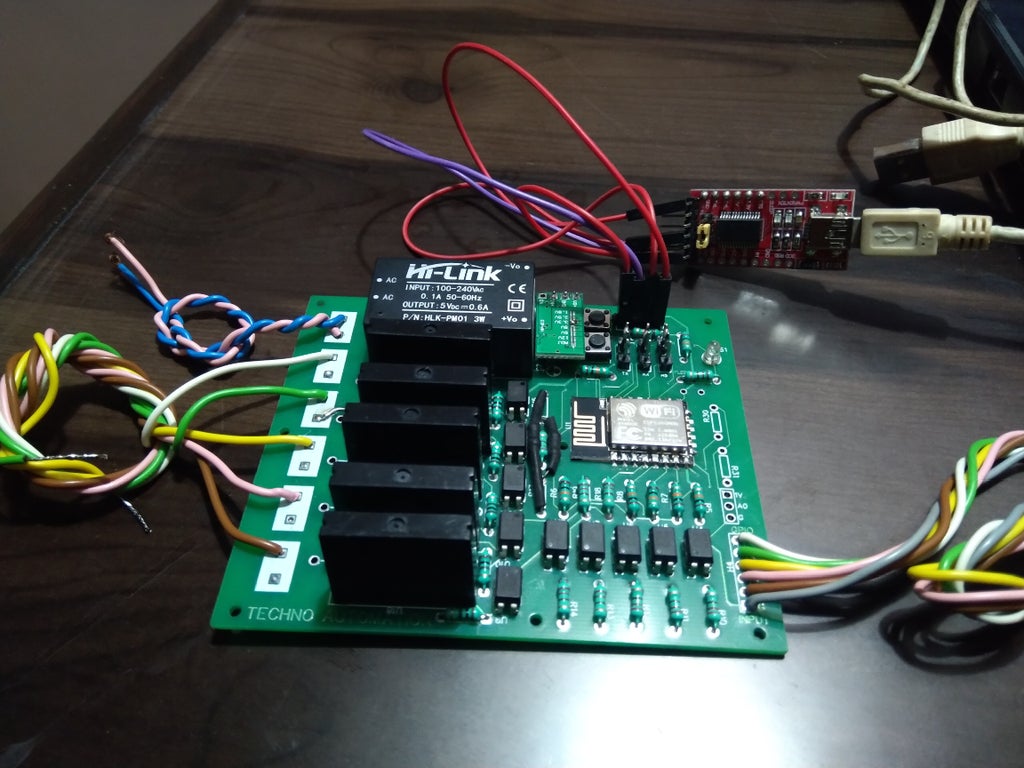

- Front View after soldring all componants

Step 20: Power Track Thickness Increasing.

- For power connection tracks I put open tracks during PCB layout process.

- As shown in image all power traces are open so poured extra soldering on it to increase currant caring capacity.

Step 21: Final Checking

- After soldering of all components cheked all components using multimeter.

- Resistor value checking

- Optocoupler LED checking

- Grounding checking.

Step 22: Flashing Firmware.

- Three jumpers of PCB are used to put esp in boot mode. Jumper identificatino is as below.

- Check Power selection Jumper on 3.3VDC of FTDI Chip.

- Connect FTDI chip to PCB

- Wiring of FTDI to PCB as below.

- FTDI TX :- PCB RX

- FTDI RX :- PCB TX

- FTDI VCC :- PCB 3.3V

- FTDI G :- PCB G

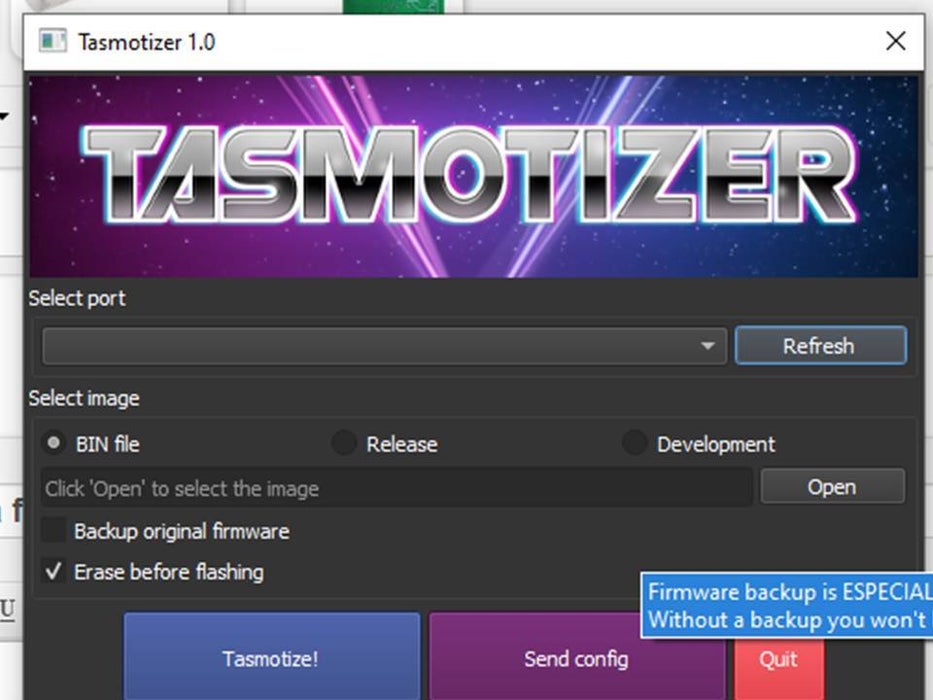

Step 23: Flash Tasamota Firmware on ESP8266

- Steps for Tasmota fleshing is as below.

- Download Tasamotizer which is fleshing tool for esp8266 board

- Download tasmota firmware pre compiled bin file known as:- Tasmota.bin

- Install tasmotazer and open it.

- In tasmotizer click select port drill dawn button.

- if FTDI is connected then port appear in list.

- Select port from list.(in case multiple port, check which port is of FTDI)

- click open button and Select Tasamota.bin file from download location.

- click on Erase before flashing option(clear spiff if any data is there)

- Press Tasamotize! Button

- if everything is ok then you get progressbar of erasing flash.

- once process completed it shows "restart esp" popup.

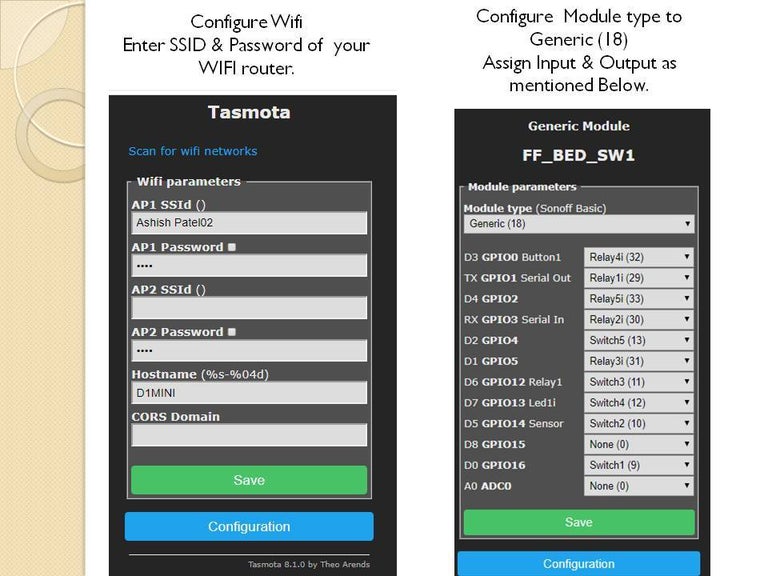

Step 24: Seting Tasmota

- Tasmota configration online help:-Tasmota configration help

- Connect AC power to PCB

- ESP will start and Status led of PCB flash once. Open Wifimanger on Laptop and search for new AP named start with "Tasmota"

- Connect Tasmota Network which didnt ask for password. once connected webpage opened automatically.

- If Webpage not opened then open Webpage and enter 192.168.4.1 and hit enter will pen tasmot configuration page.

- Configure WIFI ssid & Password of your router in Configure Wifi page( Two Wifi Ap can also saved by Tasmota).

- Device will restart after saving.

- Open your router, check for new device ip & note its IP.

- open webpage and enter that newly connected IP in Webpage to start device setting.

- Set Module type(18) in configure module option and set all input & output as mentioned in configuration image shown above.

- restart PCB and its good to go.

Step 25: Wiring Guide and Demo

- Final Wiring & Trial of PCB

- Wiring of all 5 inputs are connected to 5 Switch/Buttone.

- Second connection of all 5 device is connected to Common "G" wire of input header.

- Output side 5 Wire connecton to 5 home appliance.

- Give 230 to input of PCB.

- Smart Swith with 5 Input & 5 Output is ready to use.

Demo of trial :- Demo on Youtube is hear.

Step 26: To DO list for future.

- Power connection track thinking.

- PCB size optimization.

- Adding 6th SSR with GPIO2 which can controlled by Analogue input.

.webp)