https://www.digikey.in/en/mylists/list/UVFM67HJ8A

Step 1: Collecting Components

I started by gathering all required components:

- Seeed XIAO ESP32S3 / ESP32 board

- MPU6050 vibration/accelerometer sensor

- Breadboard

- Jumper wires

- USB cable

- Laptop with Arduino IDE & Node.js

These were enough to build the full prototype.

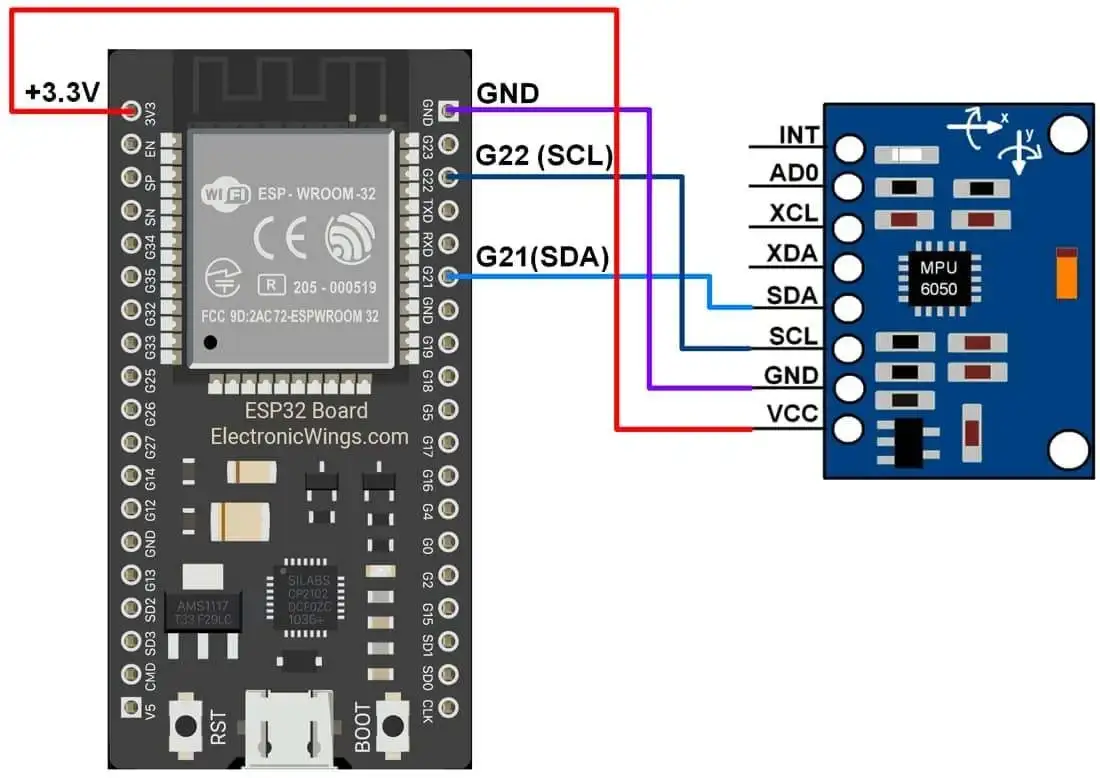

Step 2: Wiring the Sensor

The MPU6050 was connected to the ESP32S3 using the I2C interface:

- VCC → 3.3V

- GND → GND

- SDA → GPIO 21

- SCL → GPIO 22

Step 3: Testing Sensor Readings

I uploaded a simple code in Arduino IDE to read raw accelerometer values from the MPU6050.

When I shook or tapped the sensor, I could see the values change on the Serial Monitor.

This confirmed that:

- Connections were correct

- Sensor was working

- Data was being received properly

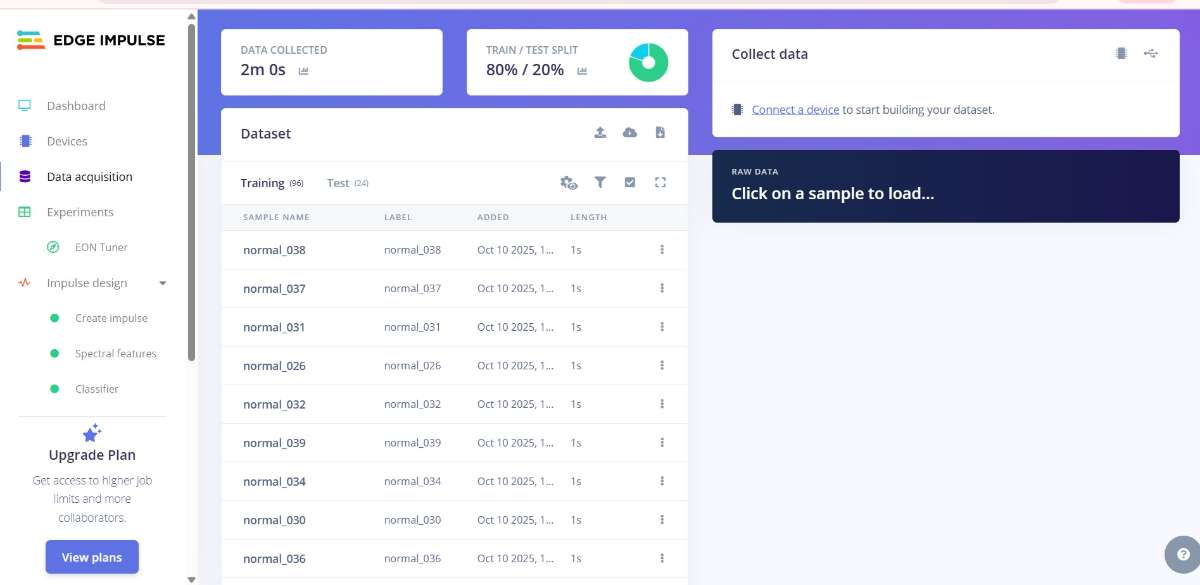

Step 4: Collecting Vibration Data

Next, I collected vibration samples from a motor under different conditions:

- Normal running

- Loose mounting

- Misalignment

- Added load

- High vibration state

I saved these vibration readings as CSV files to use them for training the vibration detection model.

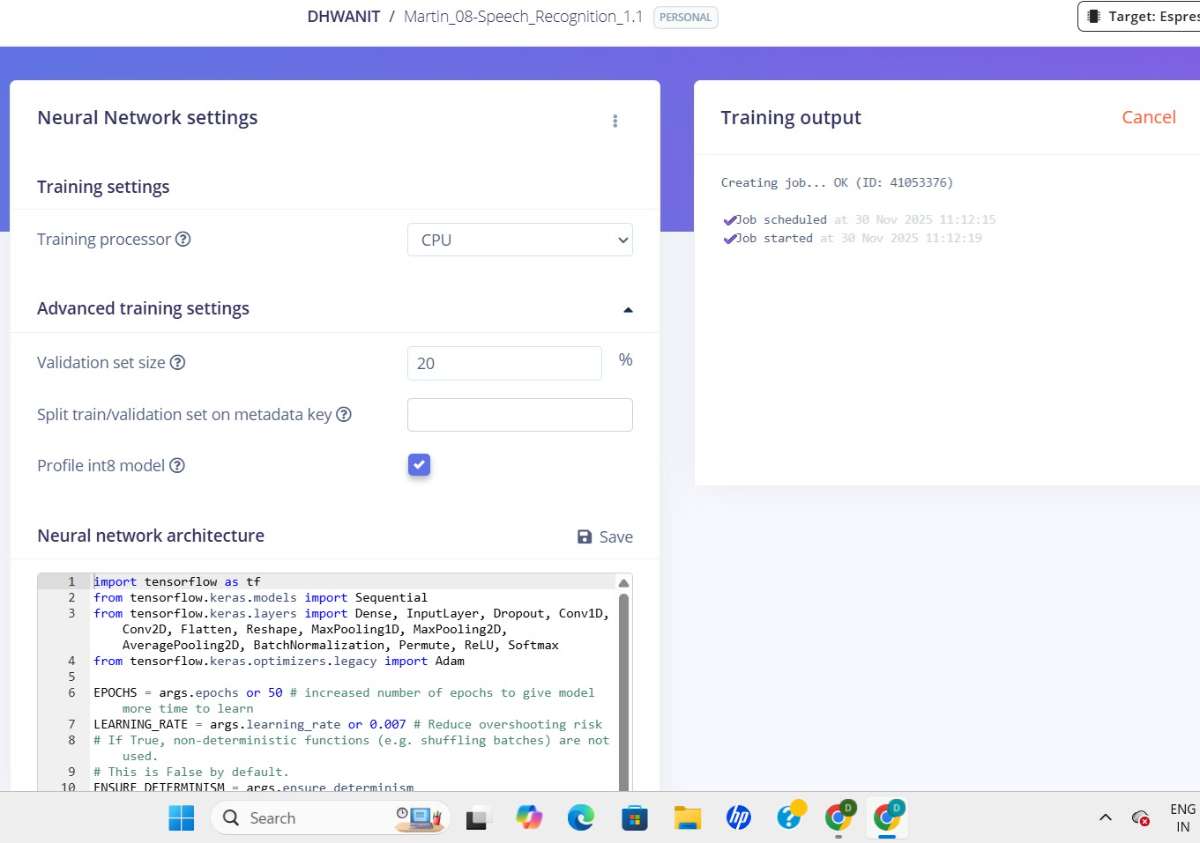

Step 5: Creating the Vibration Model

I processed the collected data and created a lightweight vibration classification model.

I mainly used:

- Time-domain vibration patterns

- Frequency features (FFT)

This model learns the difference between normal and abnormal vibration levels.

Once the model was ready, I exported it so that it could be deployed on the ESP32.

Step 6: Uploading Model to Microcontroller

I added the exported vibration detection model into my ESP32 code.

Now the microcontroller:

- Continuously reads vibration data

- Processes it

- Compares it with the trained model

- Detects abnormal vibration patterns

Whenever an abnormal vibration is detected, the ESP32 sends an alert message to the Node.js dashboard.

Step 7: Building the Real-Time Dashboard

I built a small Node.js server that receives alerts from the ESP32.

It shows:

- Alert message

- Timestamp

- Motor status

- Confidence level

This dashboard updates instantly whenever the ESP32 detects a vibration anomaly.

Step 8: Testing the Complete System

I mounted the sensor on a motor and performed various tests:

- Artificially loosening the screws

- Adding extra weight

- Changing speed

- Running the motor under stress

The system correctly detected abnormal vibration levels every time.

#include <Wire.h>

#include <MPU6050.h>

MPU6050 mpu;

void setup() {

Serial.begin(115200);

Wire.begin(); // SDA = 21, SCL = 22 (default for ESP32)

mpu.begin();

mpu.calcGyroOffsets(); // Auto-calibration

delay(2000);

Serial.println("accX,accY,accZ,gyroX,gyroY,gyroZ");

}

void loop() {

mpu.update();

Serial.print(mpu.getAccX()); Serial.print(",");

Serial.print(mpu.getAccY()); Serial.print(",");

Serial.print(mpu.getAccZ()); Serial.print(",");

Serial.print(mpu.getGyroX()); Serial.print(",");

Serial.print(mpu.getGyroY()); Serial.print(",");

Serial.println(mpu.getGyroZ());

delay(20); // 50 Hz sampling (20 ms)

}

What this code does:

- Reads 6 DOF data (Accel + Gyro)

- Outputs CSV format (compatible with Edge Impulse Data Forwarder)

- Samples at 50 Hz (change

delay()for faster/slower sampling)

Recommended Edge Impulse Impulse Settings (Perfect for Vibration/TinyML)

Sampling Parameters

| Setting | Recommended Value |

|---|---|

| Sampling Frequency | 100 Hz (best for motors) |

| Window Size | 1000 ms (1 second) |

| Window Increase | 200 ms |

Why?

1 second gives enough vibration cycles for FFT, 100 Hz satisfies Nyquist, and 200ms provides overlap for smooth inference.

Add ING a Processing Block

Select Spectral Features (FFT) FOR configure:

FFT Settings:

| Parameter | Value |

|---|---|

| Scale type | Raw |

| FFT length | Power of 2 (512) |

| Filter | None |

| Zero padding | Yes |

| Frequency bands | Auto-split (recommended) |

Additional Statistical Features: RMS, Standard Deviation, Mean, Kurtosis. Skewness, Peak-to-Peak

These features improve anomaly detection significantly.

Learning Block

Choose one:

TinyML Classifier (Best for 2-class: Normal vs Abnormal)

K-means Anomaly Detection

Best for detecting unknown faults.

Model Settings

Learning Rate: 0.005

Epochs: 40–60

Batch Size: 32

Quantization: Int8 Optimized (for ESP32)

(3) Complete Node.js Backend + Frontend

This creates a real-time alert dashboard using Express + Socket.io.

server.js

const express = require("express");

const http = require("http");

const { Server } = require("socket.io");

const path = require("path");

const app = express();

const server = http.createServer(app);

const io = new Server(server);

app.use(express.json());

// Receive alert from ESP32

app.post("/alert", (req, res) => {

console.log("Incoming Alert:", req.body);

io.emit("vibration-alert", req.body);

res.sendStatus(200);

});

// Serve dashboard

app.use(express.static(path.join(__dirname, "public")));

io.on("connection", () => {

console.log("Dashboard Connected");

});

server.listen(3000, () => {

console.log("Server running on http://localhost:3000");

});

Dashboard UI

Create a folder named public → Inside it create index.html:<!DOCTYPE html>

<html>

<head>

<title>Vibration Monitoring Dashboard</title>

<script src="/socket.io/socket.io.js"></script>

<style>

body { font-family: Arial; background:#f4f4f4; padding:20px; }

.alert-box {

background:#ffdddd; border-left:5px solid red; padding:15px;

margin-bottom:10px; border-radius:8px;

}

</style>

</head>

<body>

<h2>Real-Time Vibration Alerts</h2>

<div id="alerts"></div>

<script>

const socket = io();

socket.on("vibration-alert", (data) => {

const box = document.createElement("div");

box.className = "alert-box";

box.innerHTML = `

<strong>⚠ Abnormal Vibration Detected!</strong><br>

Device: ${data.device}<br>

Confidence: ${data.confidence}<br>

Time: ${new Date().toLocaleString()}

`;

document.getElementById("alerts").prepend(box);

});

</script>

</body>

</html>

Run

Run these commands:npm init -y

npm install express socket.io

node server.js