Introduction

The massive consumption of a wide range plastic products has generated a huge amount of plastic waste. There is a need to provide awareness of their uses and routine management as a part of our lifestyle. Nowadays, plastics are increasingly being used in our daily life activities, including the packaging in different food and brewing companies, cosmetics, pharmaceutical, and other production sectors need to pack their end products for efficient and safer product's delivery to the community. Recycling of plastics into new source. Plastics are collected from home products (shampoo cover, plastic cover) and are converted into renewable.

Renewable plastics are recycled into new product. there is seven types of plastics. Among that PET and HDFE are the two types of plastics mostly used in day to day life. Landfills, Pyrolysis, recycling, bioremediation, Incineration are the methods can be used for plastic waste management. Among these recycling is the best method to recycle the plastics. because other methods would take more time and process is so lengthy. Moreover, the product from those process cannot be recycled for many times. So recycling is the best method to recycle PET and HDFE. Collecting the plastics from the household. Sorting them into type needed for the recycling. Shredding is the main process to cut the plastics into pieces. The cut pieces of plastics are taken by the conveyor belt. The washing is the method to wash and dry the plastic pieces. The melting is the used to heat and melt the plastic at constant temperature. The new recycled product is obtained. The recycling plastics can be recycled into at least ten times. In Canada researchers are going on developing these plastics into a new renewable by product.

Step by step procedure

Step 1: Problem statement finding and declaration.

- Due to wastage of plastic it causes air pollution, water pollution etc.

- Due to that it also affects the health of human begins and causes many health issues. Larger items, such as plastic bags and straws, can choke and starve marine life, while smaller fragments (micro plastics) can cause liver, reproductive, and gastrointestinal damage in animals.

- Secondly in forest region it affects animal’s life and growth of trees too

- The most visible impacts of plastic debris are the ingestion, suffocation and entanglement of hundreds of marine species. Marine wildlife such as seabirds, whales, fish and turtles mistake plastic waste for prey; most then die of starvation as their stomachs become filled with plastics.

Step 2: Finding a standard solution to the problem statement.

Some methods are established to have a clean environment and good plastic waste disposal. They are landfills, incineration, bioremediation, recycling and pyrolysis. Recycling of plastics into new source. Plastics are collected from home and are converted into renewable. Renewable plastics are recycled to new product .Recycling of plastics into byproducts or raw material. Raw materials are used in the road construction and railway track construction. By products can be recycled up to 10 times.

Step 3: Making the requirements for the project

Step 4: Programming the node mcu with the requirements according to the system and to make the hardware to communicate with machine

Step 5: Testing overall communication from the application to the hardware and relay module and testing the relay module first with the battery powered appliance.

Step 6: Finally testing the overall system with a real time appliance with the power supply.

Step 7: Building the prototype and the system is ready

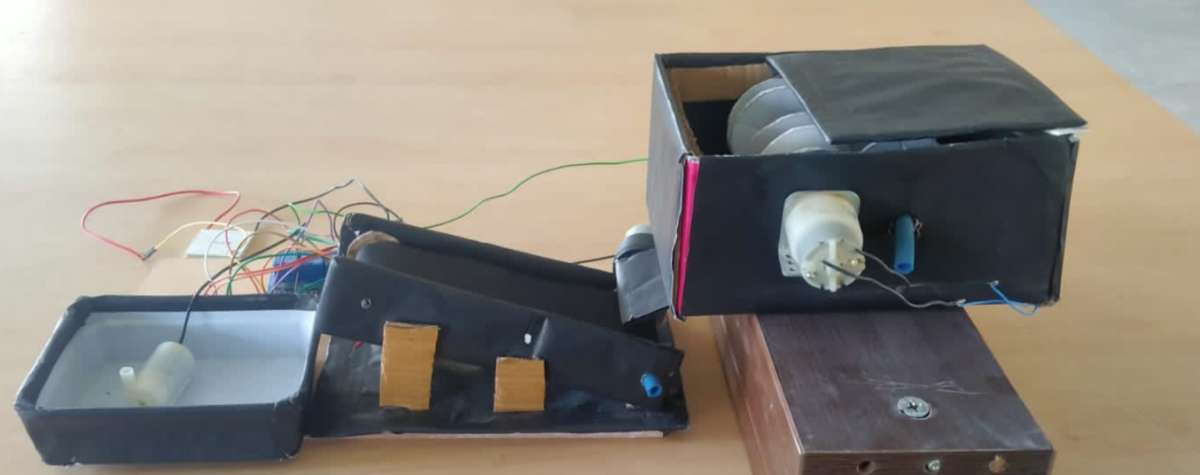

PROTOTYPE: